So recently I have begun to leak and burn oil, no tests have been done but everything points to the head gasket and most likely rings. I have had a slight rod knock for the last 8 months, and lately its getting louder. I have developed a leak from my oil pressure sensor, my dizzy seal, cam seal, and finally, the front main seal.....yeah, from everywhere. Also, my drivers side boot on the steering rack has torn, and I drip power steering fluid all the time, but the reservoir remains full. The front brakes are starting to grind, and they toss up dust like mad.

So the plan is a full tear down and rebuild of the engine, but on the semi cheap. There are no aftermarket components going into the engine, just OEM replacements. The schedule is planned to start this Thursday, and I hope to have it done in a week, 2 tops. I guess it all really depends on the machine shop's speed on the block hone. I plan this to be a semi-blog type of thread, to track and share progress with the forum. Who knows, maybe I will inspire someone to do their own rebuild, that's my intent.

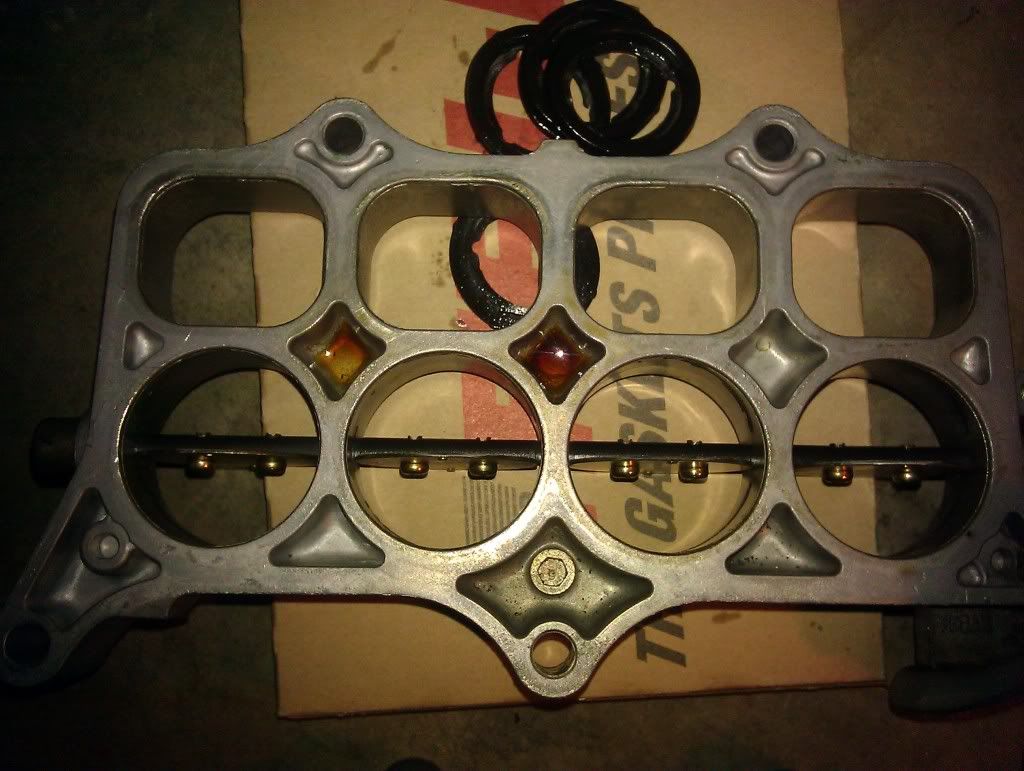

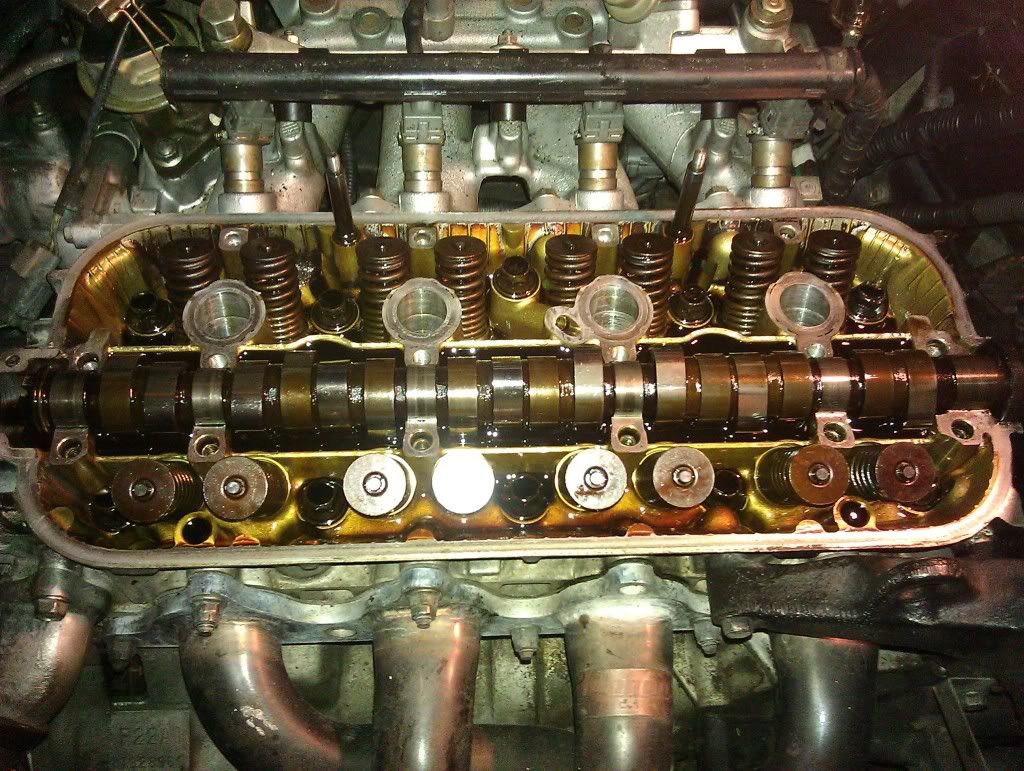

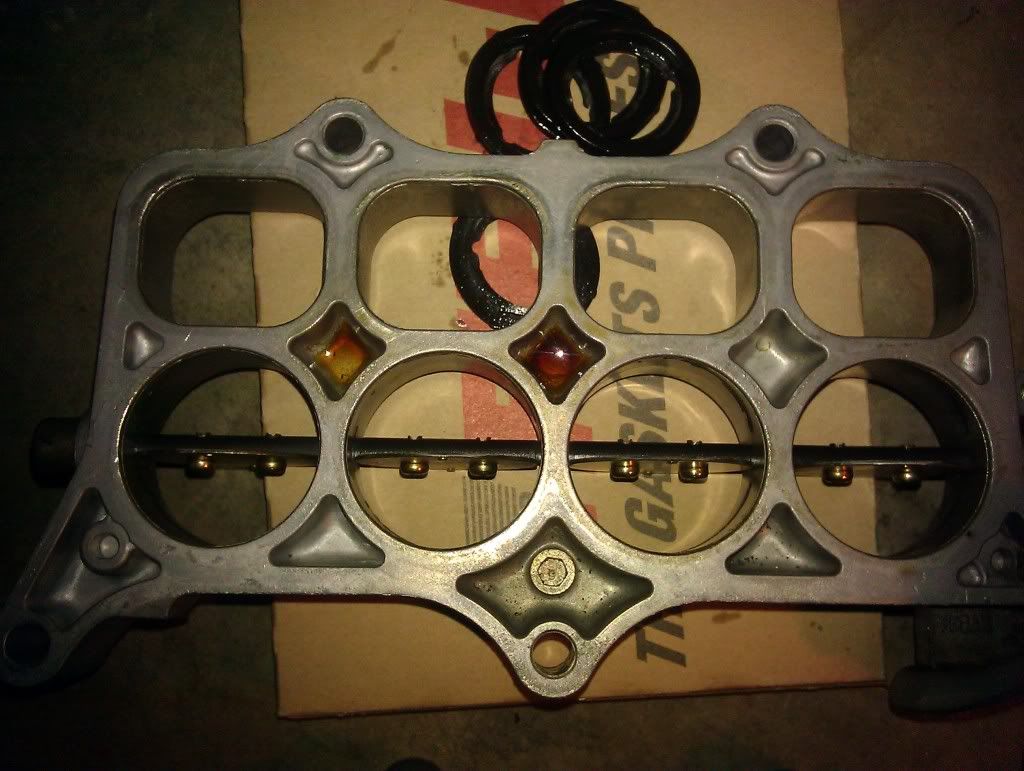

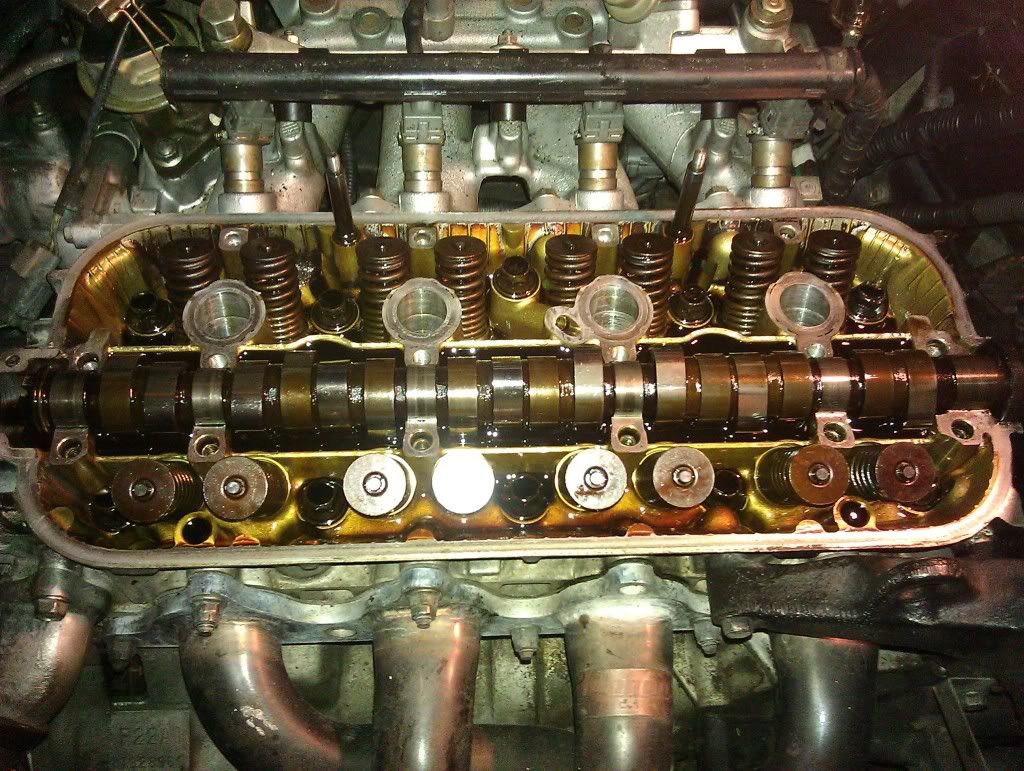

So here is where I started, about 2 weeks ago. I got fed up with leaking oil from under my dizzy and cam seal, and decided to take action. And I also tore open the plenum to inspect for oil because I was spitting out blue clouds of smoke on take-off. Here's what I found:

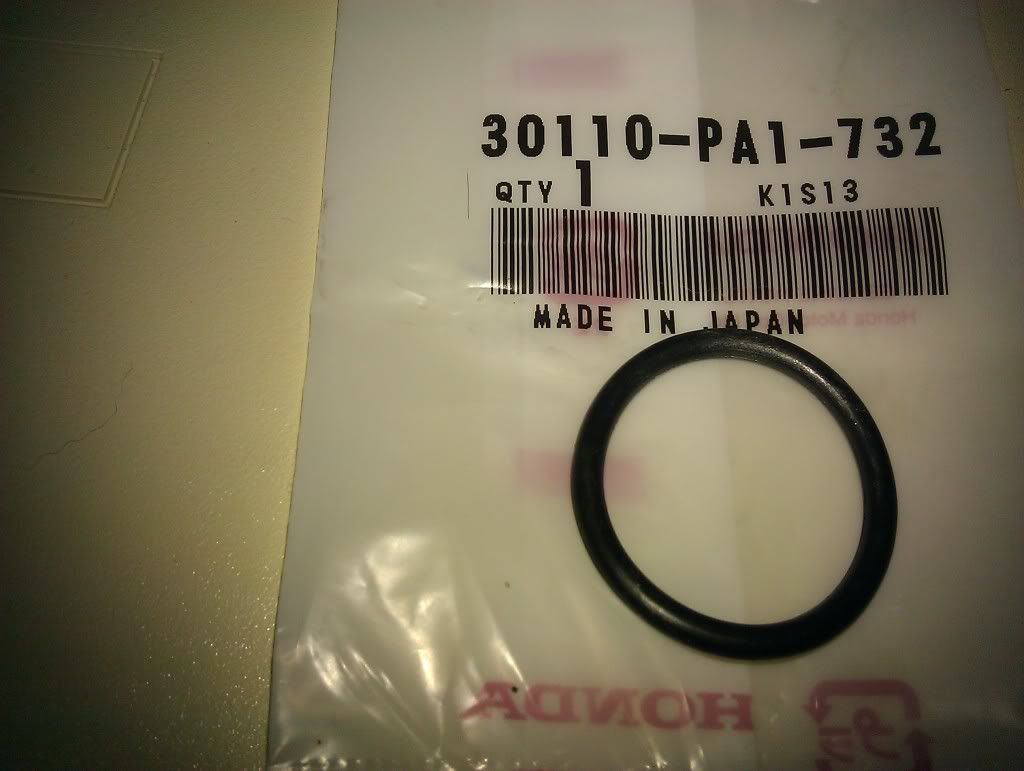

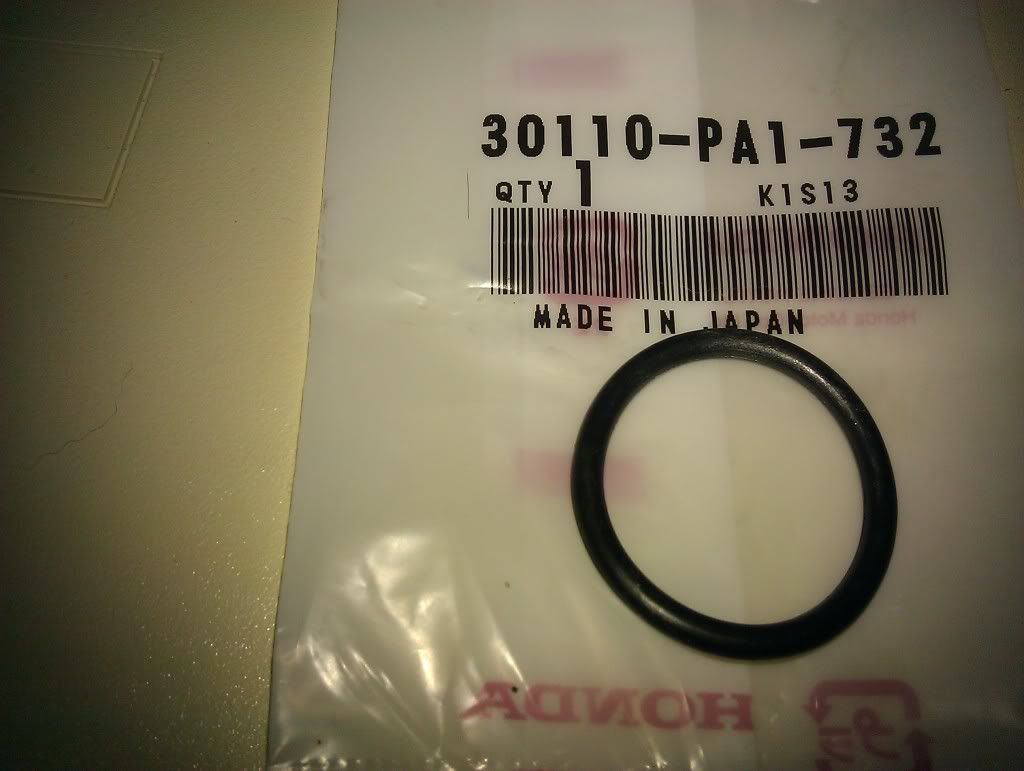

Not very fun if you ask me, but it had to be done, I was tired of leaking oil everywhere. I got a FelPro valve gasket set, Moog cam seal, an OEM Honda dizzy seal, and then got to work. And here are some of those pics:

So the plan is a full tear down and rebuild of the engine, but on the semi cheap. There are no aftermarket components going into the engine, just OEM replacements. The schedule is planned to start this Thursday, and I hope to have it done in a week, 2 tops. I guess it all really depends on the machine shop's speed on the block hone. I plan this to be a semi-blog type of thread, to track and share progress with the forum. Who knows, maybe I will inspire someone to do their own rebuild, that's my intent.

So here is where I started, about 2 weeks ago. I got fed up with leaking oil from under my dizzy and cam seal, and decided to take action. And I also tore open the plenum to inspect for oil because I was spitting out blue clouds of smoke on take-off. Here's what I found:

Not very fun if you ask me, but it had to be done, I was tired of leaking oil everywhere. I got a FelPro valve gasket set, Moog cam seal, an OEM Honda dizzy seal, and then got to work. And here are some of those pics:

Comment