Originally posted by GearBangnAccord

View Post

Announcement

Collapse

1 of 2

<

>

ANY BUYING/SELLING IN THIS FORUM WILL RESULT IN AN INSTANT BAN!

Read the rules: http://www.cb7tuner.com/vbb/showthread.php?t=43956

Myself, and the other mods have been very nice and lenient with the rules. We have been deleting threads, and giving out warnings. Some members didn't get the clue and re-posted over and over... Now ANY member buying or selling in this section will be banned... No IF's AND's or BUT's.

Myself, and the other mods have been very nice and lenient with the rules. We have been deleting threads, and giving out warnings. Some members didn't get the clue and re-posted over and over... Now ANY member buying or selling in this section will be banned... No IF's AND's or BUT's.

2 of 2

<

>

Beginner Forum Rules - EVERYBODY read! (old and new members alike!)

Beginners start here. Once you have 30 worthwhile posts (off topic doesn't count) you may post outside of the Beginner forums. Any "whoring" (posting simply to raise your post count) will return your count to 0, or result in a ban.

These are the rules. Read them. Live by them.

1) Absolutely NO flaming! "Flaming" is an outright attack on a member. ALL questions are encouraged to be asked here, no matter how basic. Members with over 30 posts will be subject to a ONE WEEK ban if caught flaming in this forum (and yes, moderators can read deleted posts). Members with under 30 posts will be subject to a ONE DAY ban.

2) Use appropriate language. Racial or sexual slurs will not be tolerated. A ban will be issued at the discretion of the cb7tuner.com staff.

3) No items may be sold in the Beginner forums. Any "for sale" threads will be deleted.

4) Temporarily banned members will be PERMANTLY banned if they are found posting on another account.

The rules can and will be added to. Any updates will be marked in the title.

The rules for the overall forum can be found here:

http://www.cb7tuner.com/vbb/forumdisplay.php?f=144

Read them. You will be expected to follow them.

These are the rules. Read them. Live by them.

1) Absolutely NO flaming! "Flaming" is an outright attack on a member. ALL questions are encouraged to be asked here, no matter how basic. Members with over 30 posts will be subject to a ONE WEEK ban if caught flaming in this forum (and yes, moderators can read deleted posts). Members with under 30 posts will be subject to a ONE DAY ban.

2) Use appropriate language. Racial or sexual slurs will not be tolerated. A ban will be issued at the discretion of the cb7tuner.com staff.

3) No items may be sold in the Beginner forums. Any "for sale" threads will be deleted.

4) Temporarily banned members will be PERMANTLY banned if they are found posting on another account.

The rules can and will be added to. Any updates will be marked in the title.

The rules for the overall forum can be found here:

http://www.cb7tuner.com/vbb/forumdisplay.php?f=144

Read them. You will be expected to follow them.

See more

See less

CB7 Timing Belt Procdure

Collapse

X

-

Easy HOWTO put the rubber grommet back over the timing belt tension adjuster nut

Take a 15mm short socket and stretch the grommet around the end of it. Put the socket over the adjusting nut. Push the grommet off toward the timing cover and it will contract onto the bolt.

Learned/improvised the hard way.

Comment

-

that tensioner arm does not go to the balance shaft belt pulley, it goes to the t-belt pulley...so regardless of whether the balance belt is on or off...when you FINISH, there should be no 10mm bolt in the t-belt tensioner arm...the 3rd picture in post #10Originally posted by nostringz View Postlol but i plan to leave the balance belt off anyway.__ __

__

Comment

-

why does leaving the 10mm bolt on the tensioner adjuster arm create any problems

I left my 10mm bolt in there (with 3 washers) with blue loctite. Reason being, my adjuster nut is stripped so I can't guage the torque I put on it (I had to tighten the adjuster nut with a vise-grip!) and I want to put sole trust it to hold the tension settings over time. I also didn't want to overtension the adjuster nut to compensate, so settled on securely installing that 10mm bolt on the arOriginally posted by bcjammerx View Postthat tensioner arm does not go to the balance shaft belt pulley, it goes to the t-belt pulley...so regardless of whether the balance belt is on or off...when you FINISH, there should be no 10mm bolt in the t-belt tensioner arm...the 3rd picture in post #10

m as a reasonable backup measure.

I have had the car to 5000 rpms and no problem so far, runs smooth (actually, it runs smoother than i ever remember it after this t.b. change) I see little reason that a properly tensioned belt with a nut on the adjuster arm would perform any differently than one without the nut.

The only difference would be that you can't readjust the timing belt tension from outside the covers when that nut is installed on the tensioner arm, and Honda wanted to make the belt adjustable from outside the covers. To me that is the sole purpose of not installing a nut on the tensioner arm.

T.B. tension *does not* change according to rpm, as the pulleys are set firmly in place once you tighten the big 14mm adjuster nut .

I realize that if/when the belt starts to stretch, I have to go again under the timing covers to reset the tension, but that *should* be the only problem/drawback with leaving that 10mm bolt on the tension adjuster arm.

I was concerned by bcjammerx's statement that the "10mm bolt will not stay there". Did you mean that the bolt will come out for some unknown reason, or that you're just not supposed to leave it there?

The only reason I can think of (and believe me, i thought about this before doing it) that leaving that bolt there would cause a problem would be (a) if it vibrated loose and got out, damaging or breaking the timing belt depending on where it landed or (b) if the slight deflection of the timing belt tensioner arm that the tightened bolt creates somehow stresses the bearing such that the bearing fails. I rate either risk as being small, as the 10mm bolt is tensioned and has loctite. issue (b) is more probably, but there really isn't that much deflection of the tension adjuster arm at all against the block (like maybe 3 hair's worth).

I am just throwing this out to get more info as it is a matter of some importance to me!Last edited by batever; 06-18-2009, 08:42 PM.

Comment

-

So which is it, the top of the tooth or the valley of the groove, that you align with the cylinder head? You sound like you are saying both here.Originally posted by 203CB7TUNER View PostSo here I am thinking that the crank is not lining up with the cam when the cam itself isn't set right. You have the up mark on the cam gear and the tdc grooves 90* perpendicular. Use the GROOVES to line the cam flush with the top of the cylinder head.

The reason I say that is because the engine is slanted back and the up mark on the cam gear can be decieving. Mark the grooves and get up close and make sure they are lined with the head dead on. If you are looking at the cam gear from the driver's side the top of grooved tooth on the gear should line up with the head surface. If you do that it should be one shot one kill type of deal. This applies to the F22 btw.

I'm interested in this because I just went by the side marker arrows on the camshaft pulley, not the tooth peak or tooth valley.

Comment

-

I haven't noticed that problem with my car; perhaps it's actually because your belt is slightly undertensioned and the timing belt slap is showing up only at higher rpms??Originally posted by GearBangnAccord View Postdont leave the bolt like he said the results are not being able to rev high. I left mine in it runs but when i go higher than 4800 rpm i hear the belt slapping in every gear

Comment

-

I've done quite a few tbelt jobs, some 200k past due and imho the tbelt wont strech far enough under severe duty on a stock engine to make retensioning a legitimate concern.Originally posted by batever View PostI left my 10mm bolt in there (with 3 washers) with blue loctite. Reason being, my adjuster nut is stripped so I can't guage the torque I put on it (I had to tighten the adjuster nut with a vise-grip!) and I want to put sole trust it to hold the tension settings over time. I also didn't want to overtension the adjuster nut to compensate, so settled on securely installing that 10mm bolt on the ar

m as a reasonable backup measure.

I have had the car to 5000 rpms and no problem so far, runs smooth (actually, it runs smoother than i ever remember it after this t.b. change) I see little reason that a properly tensioned belt with a nut on the adjuster arm would perform any differently than one without the nut.

The only difference would be that you can't readjust the timing belt tension from outside the covers when that nut is installed on the tensioner arm, and Honda wanted to make the belt adjustable from outside the covers. To me that is the sole purpose of not installing a nut on the tensioner arm.

T.B. tension *does not* change according to rpm, as the pulleys are set firmly in place once you tighten the big 14mm adjuster nut .

I realize that if/when the belt starts to stretch, I have to go again under the timing covers to reset the tension, but that *should* be the only problem/drawback with leaving that 10mm bolt on the tension adjuster arm.

I was concerned by bcjammerx's statement that the "10mm bolt will not stay there". Did you mean that the bolt will come out for some unknown reason, or that you're just not supposed to leave it there?

The only reason I can think of (and believe me, i thought about this before doing it) that leaving that bolt there would cause a problem would be (a) if it vibrated loose and got out, damaging or breaking the timing belt depending on where it landed or (b) if the slight deflection of the timing belt tensioner arm that the tightened bolt creates somehow stresses the bearing such that the bearing fails. I rate either risk as being small, as the 10mm bolt is tensioned and has loctite. issue (b) is more probably, but there really isn't that much deflection of the tension adjuster arm at all against the block (like maybe 3 hair's worth).

I am just throwing this out to get more info as it is a matter of some importance to me! So I personally dont believe it matters if you leave the tension arm bolt in or out. Of course there is the chance that it will walk out and well thats a different concern. Flapping belts is most likely the result of undertensioning in the beginning.

So I personally dont believe it matters if you leave the tension arm bolt in or out. Of course there is the chance that it will walk out and well thats a different concern. Flapping belts is most likely the result of undertensioning in the beginning.

Comment

-

Thanks for the feedback, Fake Thug. In the end I went back in and removed it as I had to go back in anyway because I had misaligned the crankshaft by a tooth or more on the crankshaft timing belt pulley when doing the job, and as a result the timing was severely retarded, like maybe 9 degrees (!!) and the car had no power, like dead, under 2800 rpms. On the way back out I decided I trusted the adjuster bolt and I took that extra bolt I had put on the timing belt tensioner arm off.Originally posted by Fake Thug View PostI've done quite a few tbelt jobs, some 200k past due and imho the tbelt wont strech far enough under severe duty on a stock engine to make retensioning a legitimate concern. So I personally dont believe it matters if you leave the tension arm bolt in or out. Of course there is the chance that it will walk out and well thats a different concern. Flapping belts is most likely the result of undertensioning in the beginning.

So I personally dont believe it matters if you leave the tension arm bolt in or out. Of course there is the chance that it will walk out and well thats a different concern. Flapping belts is most likely the result of undertensioning in the beginning.

Thanks for your response though, it's always good to hear the perspective of someone who is much more experienced at this than I am .Last edited by batever; 08-30-2009, 02:25 PM.

Comment

-

I had talked to a guy one day that said he didnt use balancer shafts.Belt and or or shaft? Whats up with that? Is that possible? If so what are the pros and cons to that other than less rotating mass?http://WWW.DUBWISE.NET

My Job!

9DUBWISE 92 LXhttp://www.cb7tuner.com/vbb/showthread.php?t=142580

RHD ITR conversionhttp://www.cb7tuner.com/vbb/showthread.php?t=172577

Comment

-

It is possible to go without a balancer shafts belt. He probably just left the belt off as taking the shafts out would be a pain. Use the search function and you will find some discussions of this. It doesn't really fit under the thread title, which is for basic timing belt change/maintenance.Originally posted by 9DUBWISE View PostI had talked to a guy one day that said he didnt use balancer shafts.Belt and or or shaft? Whats up with that? Is that possible? If so what are the pros and cons to that other than less rotating mass?

Comment

-

Originally posted by CustomLowz View PostMANUFACTURER'S SUGGESTED SCHEDULED MAINTENANCE

For 1990-94 vehicles, the manufacturer recommends camshaft and balance shaft belts be replaced at 90,000 miles. For 1995-96 vehicles, the manufacturer recommends the belt be replaced at 90,000 miles for normal service or 60,000 miles for severe service.

For 1997 vehicles, normal replacement interval is at 105,000 miles or 84 months. Replace at 60,000 miles if car is regularly driven in extreme temperatures (over 110 degrees F, or under -20 degrees F).

CAUTION: This application is an interference engine. Do not rotate camshaft or crankshaft when timing belt is removed, or engine damage may occur. Inspect timing belt & balance shaft belt tensioner pullies for free-rotation, no seizure/rough-rotation. Otherwise, replace units.

REMOVAL & INSTALLATION - TIMING & BALANCE SHAFT BELTS

Removal

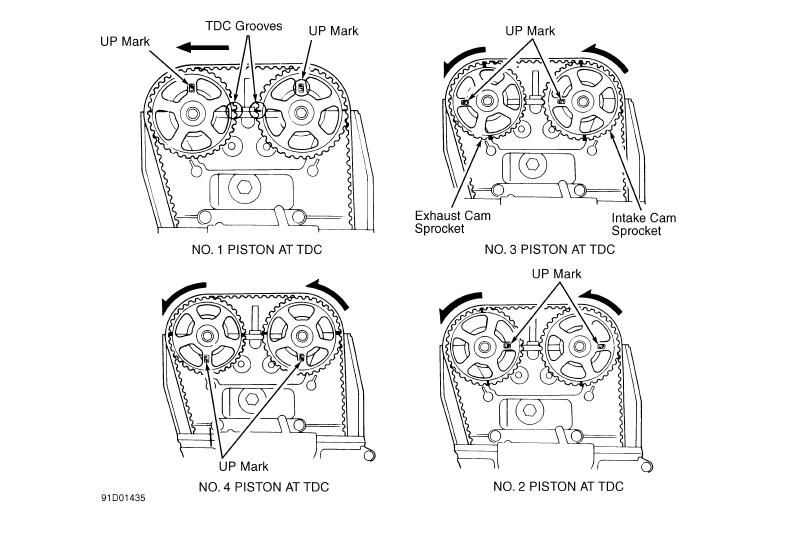

1. Disconnect negative battery cable. Position crankshaft with cylinder No. 1 at TDC of compression stroke. See Fig. 1 , Fig. 2 or Fig. 3. Disconnect battery negative cable. Remove splash shield. Remove cruise control actuator, leaving cable connected. Remove power steering pump, leaving hoses connected.

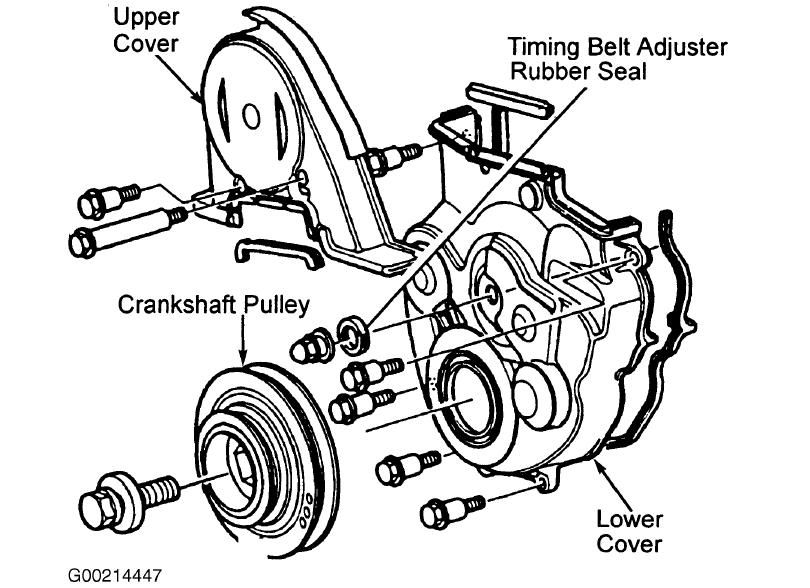

2. Disconnect alternator wiring. Remove wiring harness from valve cover. Remove alternator and A/C belts (if equipped). Remove valve cover and upper timing belt cover. Remove side engine mount. Remove engine oil dipstick and tube. Remove crankshaft pulley. See Fig. 4 .

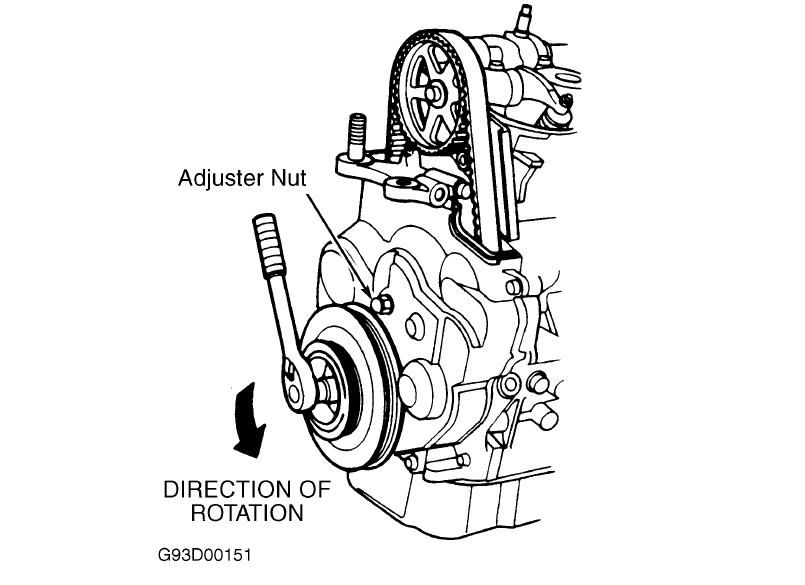

3. Support engine. Remove 2 rear bolts from engine center support beam. Lower engine enough to permit removal of lower timing belt cover. Remove rubber seal from belt tension adjuster nut. Remove lower timing belt cover.

4. CAUTION: DO NOT rotate crankshaft or camshaft when removing timing belts.

Lock timing belt adjuster arm into position by installing one lower cover retaining bolt. Loosen belt tension adjuster bolt. See Fig. 5 . Push belt tensioner to release tension from belt. Tighten adjuster bolt. Remove balance shaft and camshaft timing belts.

Fig. 1: Positioning Camshaft Sprocket for Valve Adjustment (2.2L SOHC - Accord)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 2: Positioning Camshaft Sprocket for Valve Adjustment (2.2L SOHC - Prelude)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 3: Positioning Camshaft Sprockets for Valve Adjustment (Prelude 2.3L DOHC)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 4: Removing & Installing Crankshaft Pulley (Typical)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 5: Locating Timing Belt Adjuster Nut (Typical)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Inspection

With belt or belt covers removed, inspect belts for wear, cracks, or oil soaking. Inspect belt teeth for wear. Replace belt if worn, oil soaked, or cracked.

Installation

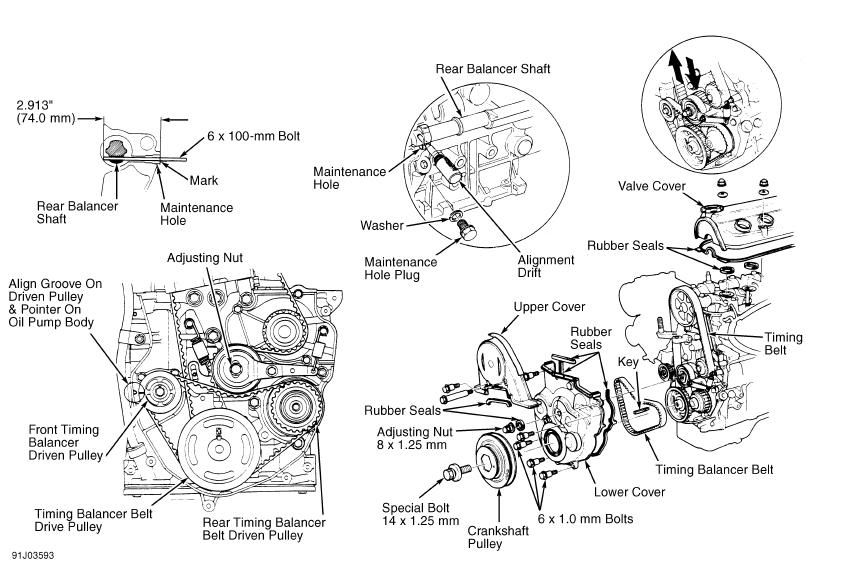

1. Align White mark on flywheel or drive plate (flexplate) with pointer on block. Ensure camshaft(s) is at TDC for No. 1 cylinder. See Fig. 1 , Fig. 2 or Fig. 3 . Install camshaft timing belt. See Fig. 6. Align rear timing balance shaft belt pulley by inserting a 6 x 100 mm bolt 2.9" (74 mm) into alignment access hole. Align groove on front balance shaft pulley with pointer on oil pump body. See Fig. 7 .

2. Adjust timing belt tension by rotating crankshaft counterclockwise until No. 1 piston is at TDC of compression stroke. Loosen, but do not remove, timing belt adjustment bolt. Rotate crankshaft counterclockwise 3 teeth on camshaft pulley to create tension on timing belt. Tighten adjustment bolt to specification. See TORQUE SPECIFICATIONS .

3. Reverse removal procedure to complete installation. Tighten crankshaft pulley bolt to specification. See TORQUE SPECIFICATIONS . Adjust drive belts to proper tension.

Fig. 6: Removing & Installing Timing & Balance Shaft Belts

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 7: Aligning Balancer Belt Driven Pulley

TORQUE SPECIFICATIONS

Application Ft. Lbs. (N.m)

A/C Compressor Bracket Bolt 37 (50)

Alternator Bracket Adjuster Bolt 16 (22)

Alternator Bracket Bolt 33 (45)

Balance Shaft Pulley Bolt 22 (30)

Camshaft Pulley Bolt

2.2L DOHC 37 (51)

2.2L SOHC & 2.3L 27 (37)

Crankshaft Pulley Bolt 184 (250)

Power Steering Belt Adjuster Nut 11 (15)

Power Steering Pump Bracket Bolt 33 (45)

Power Steering Pump Mounting Bolt 16 (22)

Shift Cable Bracket Bolt 16 (22)

Timing Belt Tension Adjuster 33 (45)

INCH Lbs. (N.m)

Timing Belt Cover Bolt 108 (12)

Valve Cover Nut 108 (12)

Water Pump Bolt 108 (12)

CB7 Timing Belt Procdure

CB7 Torque Specs

CB7 Tune-Up Specs

CB7 Fluid Capacities

DON'T START YOUR CAR UNTIL THE HARMONIC BALANCER IS ON AND TIGHT OF THE BELT WILL COME OFF!!! I almost killed my top end that way.

Comment

-

why on earth would you start the car without securing all the components first? Starting the car is the LAST thing you do...right after a double checking of all the bolts you touched...Originally posted by thepowderblue View PostDON'T START YOUR CAR UNTIL THE HARMONIC BALANCER IS ON AND TIGHT OF THE BELT WILL COME OFF!!! I almost killed my top end that way. __

__ __

__

Comment

-

Anybody who wants the Eric the car guy video, go to the DIY section and look there.Last edited by GeoffM; 02-20-2011, 10:42 PM.MRT

37.5 MPG, AC on, cruising at 80.

30.0 MPG, AC on, aggressively driving around 90.

27.5 MPG, no AC, cruising at 90 with occasional gridlock. 40 degrees Fahrenheit

Lots of DIY videos specifically for our car

Get some awesome wipers! <-- It's a DIY

Originally posted by Tippey764I think driving your car naked will cause the engine to overheatOriginally posted by deevergotesneaky motherfucker

Comment

Comment