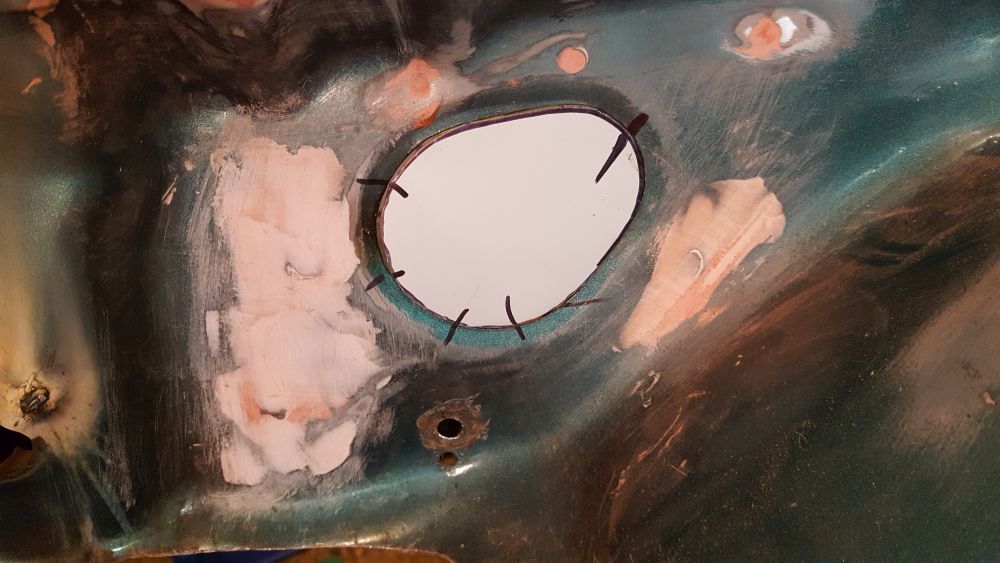

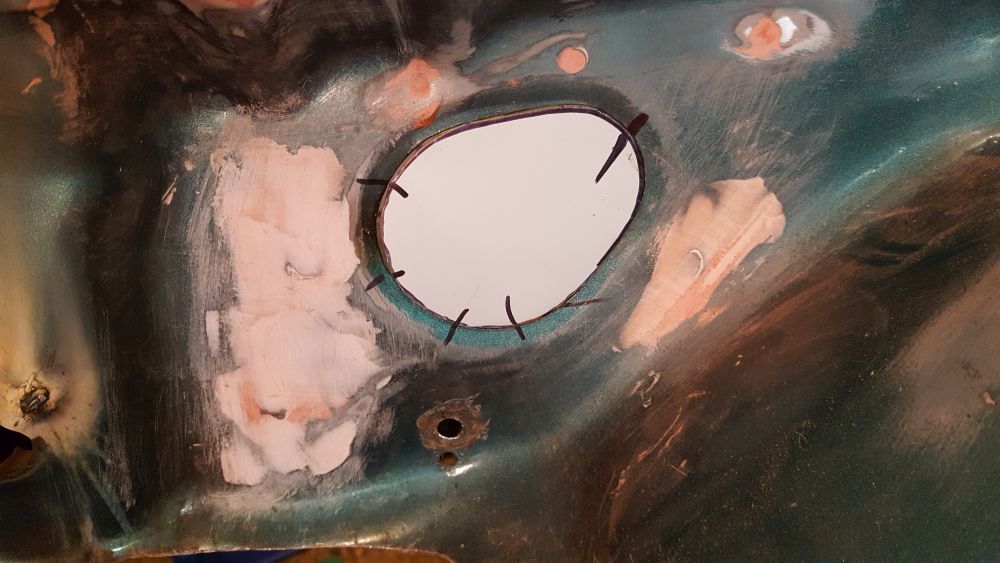

Once I got better at welding I didn't have to do so much grinding. And started to tackle holes like this one.

At this point it's a matter of welding up holes, grinding them down and putting some bondo on them. But I still had to figure out how to do the larger holes. So I got some sheet metal and figured those out too.

At this point it's a matter of welding up holes, grinding them down and putting some bondo on them. But I still had to figure out how to do the larger holes. So I got some sheet metal and figured those out too.

Most people tell me that if I had a better welder, and used gas I'd have far better results. Also that it's hard with such thin metal. I do want to learn how to weld larger stuff, like exhausts. Practice.... makes perfect here.

Most people tell me that if I had a better welder, and used gas I'd have far better results. Also that it's hard with such thin metal. I do want to learn how to weld larger stuff, like exhausts. Practice.... makes perfect here.

Comment