Hey guys. I know I don't post very often, but I'd like your input on an idea that's been growing in my head for some time. I want to build a 200whp N/a F22a1 with an H22a4 head. Now, I've been researching everything for some time and can see where I am basically at. Heres my plan.

-F22a1 block decked .020, bored 2mm over

-H22a4 head milled .030

-H23a 87mm pistons

-F22 crank

-H23 oil cooler

-F22a6 windage tray

-H22 intake runners and IAB plate

-F22a6 plenum and TB

-Stock H22 exhaust manifold

-Aiming at 11.5:1 CR

-Stock intake

-stock exhaust

-Stock injectors

-H22 secondary vtec cam lobes regrinded, leaving the primarys alone

-Internals balanced

-H23 redline

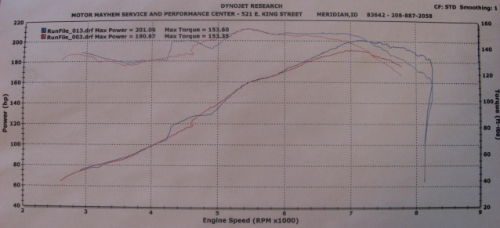

I know that Stock H22's get roughly 160-170whp stock. With what I have on my list, I've estimated 170-180whp.

I'm stumped on what ECU to use. My first thought was to just use the H22 ECU simply because its going to be an H22 vtec head. But then I thought about using the F22b1 ECU because 1) It has vtec 2)its more economical than an H22 ECU(H22's run pretty rich). Also, when Vtec kicks in, the sensors will increase fuel delivery on their own. Tying to keep fuel consumption to a minimum(at least til vtec)

If you guys haven't noticed, I'm trying to basically redevelop the F22 into a MORE efficient in both fuel and performance. I've given this a lot of thought and I haven't really found any reason why this setup would not work. I need you guys to CHALLENGE my theory because that way I have all my basis covered and will not go into this blindfolded.

Also, what else can I do to raise the hp? Something other than I/H/E please. I'm trying to keep this as stock(looking) as possible.

-F22a1 block decked .020, bored 2mm over

-H22a4 head milled .030

-H23a 87mm pistons

-F22 crank

-H23 oil cooler

-F22a6 windage tray

-H22 intake runners and IAB plate

-F22a6 plenum and TB

-Stock H22 exhaust manifold

-Aiming at 11.5:1 CR

-Stock intake

-stock exhaust

-Stock injectors

-H22 secondary vtec cam lobes regrinded, leaving the primarys alone

-Internals balanced

-H23 redline

I know that Stock H22's get roughly 160-170whp stock. With what I have on my list, I've estimated 170-180whp.

I'm stumped on what ECU to use. My first thought was to just use the H22 ECU simply because its going to be an H22 vtec head. But then I thought about using the F22b1 ECU because 1) It has vtec 2)its more economical than an H22 ECU(H22's run pretty rich). Also, when Vtec kicks in, the sensors will increase fuel delivery on their own. Tying to keep fuel consumption to a minimum(at least til vtec)

If you guys haven't noticed, I'm trying to basically redevelop the F22 into a MORE efficient in both fuel and performance. I've given this a lot of thought and I haven't really found any reason why this setup would not work. I need you guys to CHALLENGE my theory because that way I have all my basis covered and will not go into this blindfolded.

Also, what else can I do to raise the hp? Something other than I/H/E please. I'm trying to keep this as stock(looking) as possible.

You have to think outside the box to get IN the box!

You have to think outside the box to get IN the box!

Comment