Hey folks! I recently had an issue where my right turn signal would randomly turn on and the hazard/direction indicator relay would spasm. It turned out to be a worn combination switch. Most folks would simply replace the switch at this point, but here's what I did instead to save some money.

I apologize for some of the photos. I was in a hurry and getting proper lighting while using the camera on my phone is not always an easy task.

Tools and materials required:

#2 Philips screwdriver

small flat-head screwdriver

isopropyl alcohol (or acetone, or ...)

dielectric grease (silicone grease)

paper towel (or a napkin, or a rag, or ...)

cotton swaps (or cotton balls, or ...)

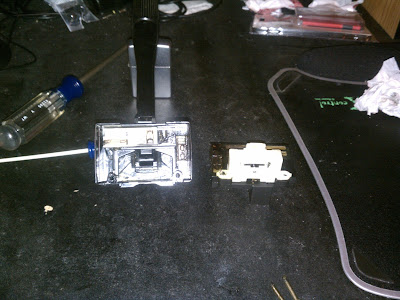

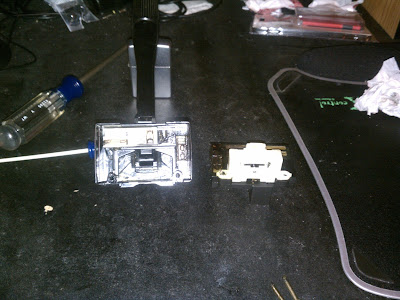

First we need to open the switch housing, the part that mounts near the steering column. To do this, first remove the two screws on the back of the housing, the side with the electrical connector. Next, insert a small flat-head screwdriver between the housing and the electrical connector module, relieving one plastic tab at a time. Finally, slide the module out.

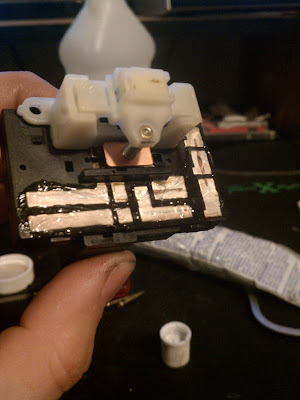

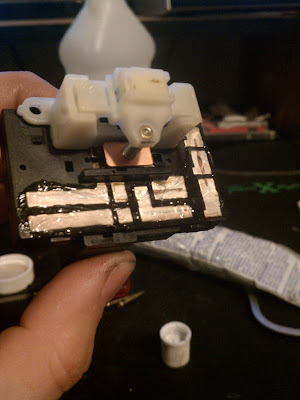

Next, clean up all of the grease, shredded plastic, and worn contacts using the alcohol, paper towels, and cotton swaps.

Finally, and this is where the magic happens, clean the gunk out from the recesses between the turn signal contacts. The turn signal contacts are the ones that run vertically on the module. I used the small flat-head screwdriver to help clear the gunk from the valley. The reason the relay comes on randomly/spastically is because the metal from the contacts mixes with the grease and builds up in the valleys between the contacts. This effectively creates a short circuit causing the switch to close, just like if you had turned the switch on normally.

Lastly, reassemble any of the sliding contacts and apply a small amount of grease to the contact surfaces. It also won't hurt to apply some grease to the mechanical plastic surfaces, so lube them up too. Install the module into the housing and insert the screws.

I apologize for some of the photos. I was in a hurry and getting proper lighting while using the camera on my phone is not always an easy task.

Tools and materials required:

#2 Philips screwdriver

small flat-head screwdriver

isopropyl alcohol (or acetone, or ...)

dielectric grease (silicone grease)

paper towel (or a napkin, or a rag, or ...)

cotton swaps (or cotton balls, or ...)

First we need to open the switch housing, the part that mounts near the steering column. To do this, first remove the two screws on the back of the housing, the side with the electrical connector. Next, insert a small flat-head screwdriver between the housing and the electrical connector module, relieving one plastic tab at a time. Finally, slide the module out.

Next, clean up all of the grease, shredded plastic, and worn contacts using the alcohol, paper towels, and cotton swaps.

Finally, and this is where the magic happens, clean the gunk out from the recesses between the turn signal contacts. The turn signal contacts are the ones that run vertically on the module. I used the small flat-head screwdriver to help clear the gunk from the valley. The reason the relay comes on randomly/spastically is because the metal from the contacts mixes with the grease and builds up in the valleys between the contacts. This effectively creates a short circuit causing the switch to close, just like if you had turned the switch on normally.

Lastly, reassemble any of the sliding contacts and apply a small amount of grease to the contact surfaces. It also won't hurt to apply some grease to the mechanical plastic surfaces, so lube them up too. Install the module into the housing and insert the screws.

Comment