How are you going to tune it without the wideband data being logged by the ECU?

If you have the AEM your going to need to get the analog + and - wires fed into the ecu wiring.

After looking at Lola and getting another S300 installed in a buddies car 2 weekends ago, and this was vital for it to become operational.

Otherwise fantastic work!

Announcement

Collapse

No announcement yet.

CyborgGT : 1993 Accord EX wagon

Collapse

X

-

It looks like S300 can read up to four channels of EGT according to this help manual if you do a search in it for "EGT", but I just have the gauge as a stand-alone tool. I probably should, but I didn't wire any of my gauges (EGT, wideband, fuel pressure, and oil pressure) into the ECU.Originally posted by daovangphotos View PostDamn, I like the bend of the intake by the throttle body.

I have clearance issues with my ABS reservoir too.

Does S300 have settings for EGT?

I may look into that setup for tuning too.Last edited by CyborgGT; 04-06-2023, 02:08 PM.

Leave a comment:

-

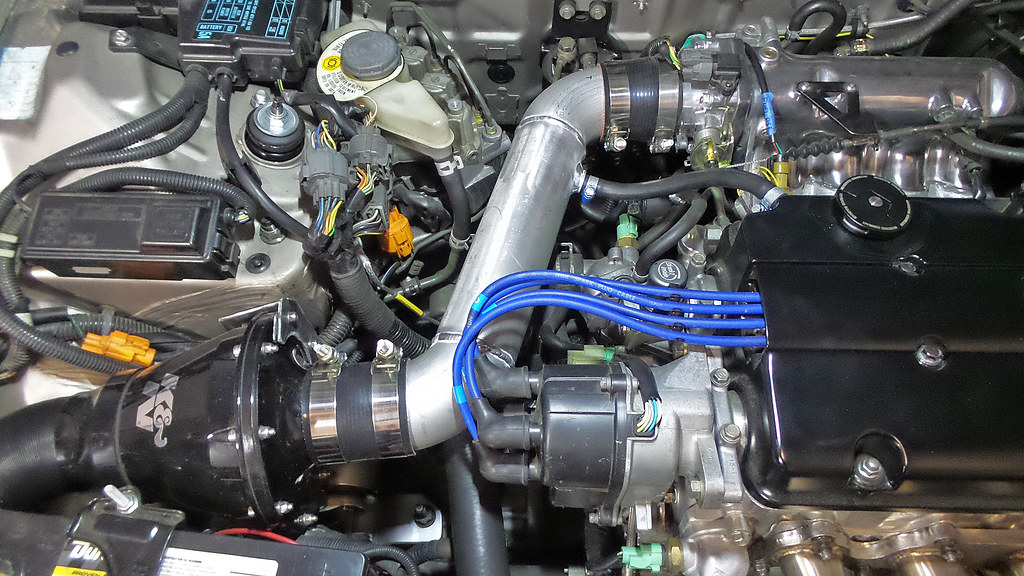

Damn, I like the bend of the intake by the throttle body.

I have clearance issues with my ABS reservoir too.

Does S300 have settings for EGT?

I may look into that setup for tuning too.

Leave a comment:

-

Just got the car back from fab. Intake and exhaust are finished (...ish), so all that's left is dyno tuning and registration!

Starting with the intake, it's a simple two-bend pipe. I wanted to retain the factory PCV system, so I cut the little tube off of my old AEM intake, but it turned out to not be weldable aluminum and just melted when they tried. So they got a fitting for me... which is, annoyingly, barbed. I tried spraying lube under that hose, but it's feeling like if I ever want to remove that end of the hose from the intake, I'm going to have to cut it off. All that's left for the intake is to paint it matte black to match my valve cover and fuel rail.

As a bonus, the guy made this beautiful little bracket to secure the filter enclosure in place, so that the whole intake isn't swinging around and potentially puncturing on that C-shaped bracket that holds the lower rad hose over the transmission. I like how he incorporated the existing bolts on the filter housing. This, too, will be painted black.

The exhaust system, on the other hand, is going to need some work later on.

I originally thought I'd get the PLM header welded up into one piece because I'll never trust slip joints, but once I got the engine in the car I quickly realized that would be a bad idea. If the header was one piece, and I were to ever want to remove it, I would have to also remove at least the alternator and A/C condenser, as well as at least the torque strut on the ESP traction bar, just to make room. That wasn't going to fly, but at least the header is now two-piece instead of its original four. I had him weld up the three-piece downpipe. You might also see in there that it has springs holding the upper and lower sections together; originally those pipes were held together by bolts that passed through loops, but once I cut the header to hug the oil pan more tightly (out of the box, it was hanging much too low for comfort), those loops no longer lined up and so I just cut them off and ordered exhaust springs & hooks.

An EGT sensor is also plugged into cylinder number three, which from what I found is the hottest cylinder on these engines. I know EGTs are intended to be used on all cylinders for the purpose of tuning each cylinder individually and making sure they're all equal, but I'm hoping that the one will at least be more useful to the tuner than none at all. The rest of the build isn't serious enough to be set up for individual cylinder tuning, but with plans to drive my wagon to every state in the US, I want a good tune. If nothing else, I suppose it looks cool, haha. Everything attached directly to the header was TIG welded, while the rest of the system was MIG'd.

But look down into the header and you'll see that I got what I paid for with my cheap aftermarket part. One of the slip joints is horribly misaligned. I'm already seeing smoke when the engine's running, but I can't yet tell if that's from the slip joint (no carbon build-up to speak of yet) or from some coating that might have come on the header. I'll leave it alone for a while, and if it turns out to be the slip joint, I'll stuff some exhaust cement in there or something. One day, when I go for 'phase 2' and start messing with bolt-ons, I'll get a HyTech.

I'll share photos of what's going on underneath the passenger compartment when I get it back on jack stands, but for now I can show off my other major issue: ground clearance where the exhaust routes under the rear suspension. There are two reasons the pipe hangs so low: 1) I don't have proper coilovers, so with the car in the air the wheels, and therefore the control arms, still droop like crazy. We didn't want to worry about the exhaust being ripped off at full droop. And 2) the Fat Four Customs LCAs aren't asymmetrical like the factory arms. Coilovers are now a higher priority than they were before, and I'll get them first to see if that solves this problem well enough, but I may end up having to swap the FFC arms for asymmetrical Cheddas Auto arms. This is, of course, assuming that I can get a proper alignment done on non-adjustable toe arms and LCAs, and don't have to get Hardrace arms instead. But even if I can tuck the exhaust high enough to not need to worry about scraping with the FFC arms, my fixation on details will always bug me if things LOOK goofy under there. We shall see...

My friend recorded the car's cold start with the new exhaust, so I'll get that up once he sends it to me. But despite the cat, two resonators, and large muffler, the car is still louder than I was hoping for. But I know mufflers with packing material have a bit of a break-in period, so we'll see if there's any improvement over time. At least it sounds fairly deep in the bottom half of the tach, though; I was worried about getting that typical high pitched rasp Hondas are known for. This fabrication work also cost much more than anticipated, so I'm back to saving up for the tune again. Next month? Fingers crossed.

Leave a comment:

-

Sending you positive CB7Tuner vibes! Hope that this is the next step in getting the Aero-R on the road.

Leave a comment:

-

Attempt number 2 at finishing up the car...

With my luck, it couldn't happen without drama, of course. I hit another delay from that first appointment because the company I've worked for for 14 years updated their employee database software and I was one of the random unlucky people who accidentally got deleted from the system. I went three weeks without getting paid, my benefits were terminated as if I had left the company, and I couldn't even log into any of the computers at work. It was kinda scary, so I put the car on hold until they sorted it out. But I'm good now, so another appointment was made.

This shop is only doing the fabrication, welding up the intake and exhaust tubing. They usually offer tuning, but don't currently have someone with that skill on staff. I might get a performance-oriented alignment here as well, since building rally, road course, and autocross cars is what they do, but we'll see. I'm not looking forward to seeing the bill on the fab work alone, given how complex my exhaust system is. They had the car up on a lift Thursday to talk about how I wanted everything done, and already the passenger side FFC control arm was causing clearance issues. It was impressive to see how accurately bent the Kteller kit was, though. With stock control arms and some proper coilovers to keep the wheels from hanging too low at full droop, it probably would have been perfect.

Leave a comment:

-

Still deciding if I really want to personalize the plate; I can't make up my mind on if I just think they're stupid altogether. Most of the ones I see are so dumb. Then there's also the fact that they're easier to remember if I happen to piss off someone in traffic, haha.

Leave a comment:

-

This is a great license plate design! I can’t wait to see what your custom plate is.

Leave a comment:

-

So I just emailed a second shop to schedule the fab/dyno (they advertise for European and the main turbocharged Japanese cars, but I believe they do have an RSX project currently going), hopefully for the end of next month, and Colorado just released these new plates for 2023 - right in time for my registration! I have an idea for a personalized plate, which means losing the center 'Race to the Clouds' logo, but still so cool! Gonna try to take the wagon to watch the race this year in June.

I have an idea for a personalized plate, which means losing the center 'Race to the Clouds' logo, but still so cool! Gonna try to take the wagon to watch the race this year in June.

Though I will say, this plate's gotta be a bit of a sting for motorcyclists, considering bikes are no longer allowed to be raced in the event due to accidents.Last edited by CyborgGT; 01-22-2023, 02:17 PM.

Leave a comment:

-

'Nother quickie. One silver lining to the delay in getting the car done is being able to upgrade little things I had regrets about. I addressed some details in the exhaust system:

- Rubber isolators. My stock ones weren't in too bad of shape, but new ones are cheap.

- Stainless hangers. The ones that came with the Kteller tubing kit were just kinda ugly, and the way they were bent (squared 'Js' instead of these 'Ls') looked like they'd be a pain to get in and out of the isolators.

- Summit stainless interlocking V-bands. I don't know if Summit didn't have interlocking bands way back when I ordered the non-interlocking style that I did, or I just didn't notice them. All I knew was that I wasn't going to pay for Vibrant's overpriced bands. But now Summit has interlocking bands, for a good price, and they even upgraded the nuts away from the nylocks that I was nervous about holding up to the exhaust heat.Last edited by CyborgGT; 01-03-2023, 09:51 PM.

- 1 like

Leave a comment:

-

Quickie update, but I got the Hella horns working yesterday. I went to the junkyard to pull a couple clock springs thinking that was my problem, given that the horns were obviously new and the both of the buttons on the steering wheel were making the relay click (I could hear and feel it activate the contacts inside, and it wasn't feeling weak), and there was nothing else in the system to go wrong other than a possible break in the wiring. So I installed one of the 'new' clock springs, only for the horns to still not sound. I had a spare relay, which I should have tested sooner since it was so easy, and after swapping it in, the horns finally fired. Glad to have that out of the way. I don't know if the horn is part of Colorado's lax emissions inspection, but I'm pretty sure a working horn is technically a legal requirement and I didn't want that to be something to delay registration.

Leave a comment:

-

I was told 3-4 months for these to arrive, and they came in 3-4 weeks. Nice. What ViS Racing calls their "Evo Style" side skirts; the Evolution model in question being I guess the E36 M3 Evo, although even the 'base' M3 had the same skirts.

My dream skirts have always been Sigmas, but I think these Evos still match the shape of my front lip really well to maintain a consistent look. They're fiberglass, which I'm not a fan of. They feel heavier than they need to be for a side skirt, I'm afraid of them breaking (not that they're thin or anything, I just don't trust the material), and the mold isn't perfect. They're going to need some solid bodywork to flatten the slight waves out. But given the CB's lack of support, I'll take what I can get. I don't get why they couldn't have been made out of plastic. My biggest fear, however, is that these will make the car a pain to put on jack stands or a lift; we'll see. I'll try to get them test fitted soon; I'm excited to see the skirts on in combo with the new lowering springs.

I will be mounting them "backwards" like Ronald did. It just looks more correct that way, with how the skirts affect the visual front-to-rear 'weight balance' of the car. Kind of like how the traditional sports car silhouette has a long hood and stubbier rear end. Or maybe it's because the car's FWD vs the BMW's RWD, I don't know...

Last edited by CyborgGT; 11-24-2022, 01:22 AM.

Last edited by CyborgGT; 11-24-2022, 01:22 AM.

Leave a comment:

Leave a comment: