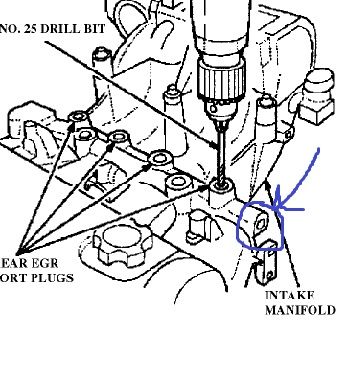

I have the replacement plug part number for the 6 top holes, but the hole on the driver side that faces horizontally is larger in diameter. I cannot find a part number for that plug. I really don't wanna use epoxy or solder for this. I just wanna hammer in a shiny new plug in the top 6 and the one on the side and be done with it.

Getting ready to do my a6/h23 + obd2 H22 throttle body + Bisi heat shield IM gasket + Urethane filled rear mount + glowshift oil pressure sandwich adapter swap.

#17199-PT3-AHM - 6 top holes.

#??????-???-??? - 1 side hole?

Getting ready to do my a6/h23 + obd2 H22 throttle body + Bisi heat shield IM gasket + Urethane filled rear mount + glowshift oil pressure sandwich adapter swap.

#17199-PT3-AHM - 6 top holes.

#??????-???-??? - 1 side hole?

If the runners are filled w/ carbon you'll be glad you removed all 7 plugs, it's good to go across via the 7th port.

If the runners are filled w/ carbon you'll be glad you removed all 7 plugs, it's good to go across via the 7th port.

Comment