This is a DIY that should not only inform you on turbo applications, but help you decide which turbo is most appropriate for your application! I will detail information about engine airflow, how to choose a flow map, and additional information on turbo selection.

Tools:

Boost Macro which you can get by providing me an email. I will try to update with a downloadable link.

Step One: Getting to know your engine.

Engine CFM (cubic feet per minute) is how much air flows through your engine in a stroke. To figure out how much air moves through your engine, follow this simple equation:

CFM = (CID x RPM x 0.5 x Ev)/1728

CID is cubic inch of displacement. 2L = 122, so to translate liters into CID just multiply Liter by 61 Ex: 1.6L x 61= 97.6CID

The 0.5 is used because only two pistons vacuum air at one point in time.

Ev is volumetric efficiency. It is the amount of air an engine draws in divided by the amount of air the engine should draw in a perfect environment. A well designed turbo engine will run at about 85%. If you have a flow meter hooked up to your engine you can measure the exact airflow at certain RPM’s and calculate the exact Ev at that RPM, this will make the calculations much more exact.

1728 is used to translate cubic INCHES into cubic FEET.

Example:

I will use my 2.2L H22A engine as a baseline and I want to pull power at 7800 RPM.

CID = 2.2L x 61CID/L = 134.2 CID

CFM = (134.2 x 7800 x 0.5 x 0.85)1728= 257.5 CFM

This means that my engine, at 7800 RPM, is pulling 257.5 cubic feet per minute.

Step 2: Understand pressure ratios.

1 Bar=14.7psi of boost. Atmospheric pressure is on average, 1 Bar. Boost is pressure above atmospheric pressure. For example, I want to increase my engines input by 14.7psi for simplicity.

Now we must find the pressure ratio.

PR = (14.7 + boost [in psi])/14.7. (14.7 + 14.7)/14.7 = 2. This means I will be running exactly 2 Bars of boost of absolute pressure, which is actually 1 Bar of Boost at atmospheric pressure.

Step 3: Apply boost to engine

257.5 CFM x 2 = 515 CFM at 14.7psi of boost. A good turbo setup for great power and good daily driving the turbo should spool up at roughly over the freeway cruising speed to ensure the engine won’t boost unless you want it to. For my engine it would be desired for the turbo to spool around 4000RPM. This will be Boost Threshold. Now I must find the flow of air at my boost threshold.

((134.2 x 4000 x 0.5 x 0.85)/1728) x 2) = 264 CFM.

Next is to find a turbo that will flow 264CFM to 515CFM at a pressure ratio of 2. Here is where the Turbo Flow Map becomes useful. For the comparison I will use Borg Warner EFR turbos since that is what I am actually looking into using. Full-race.com is a great supplier of the EFR turbos and they can be found here http://www.full-race.com/store/efr-turbos/. Conveniently they also supply the compressor maps in both English and metric. I will use English units in lbs of air.

To convert CFM to lbs, multiple CFM x .0807.

Base boost lbs = 264 x .0807 = 21.3lbs

Peak boost lbs = 515 x .0807 = 41.6lbs

Step 4: How to read a turbo flow map.

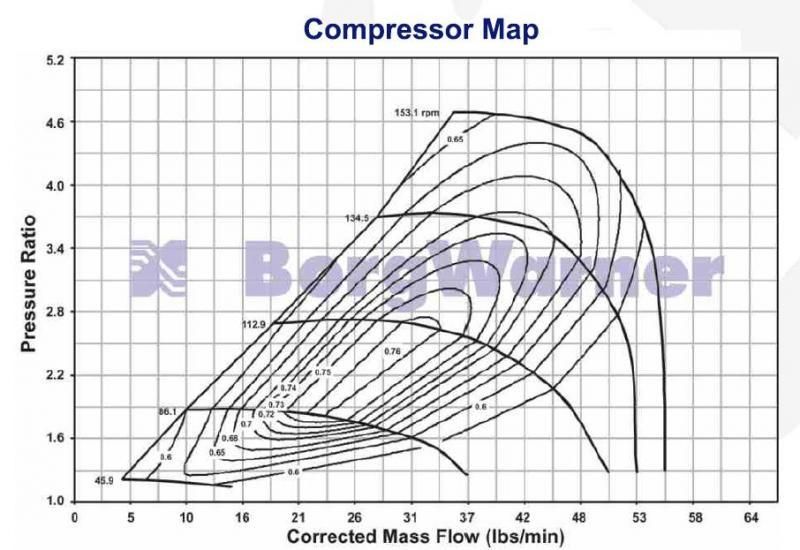

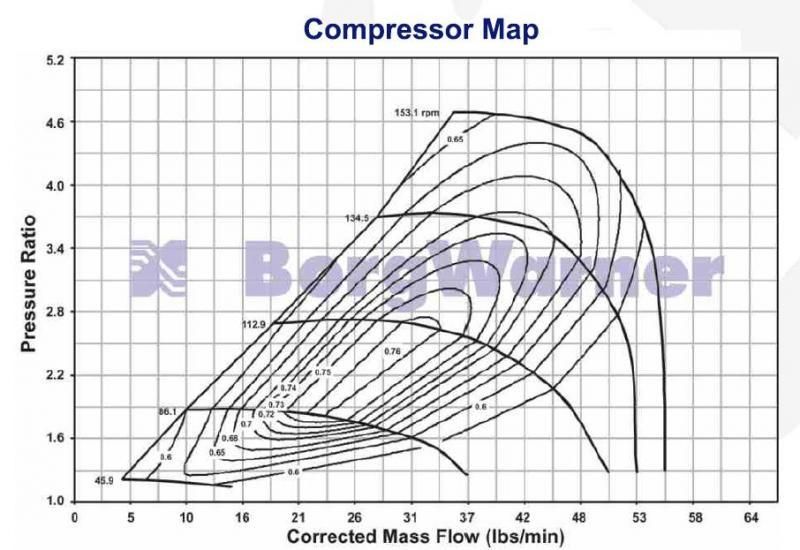

Borg Warner EFR 7064 Turbo Flow Map

This is a webpage that I found to have flow maps for the most popular/common turbos out there. Luckily it also has two conversion tables to help with converting airflow, pressure, and even approximating HP!

http://www.rbracing-rsr.com/turbotech.html

A turbo flow map show a turbos efficiency for a certain flow of air across a range of pressure ratios. They also show a few lines from left to right that represent how fast the turbo wheel is spinning. The “bubble” looking lines are efficiency ranges. The middle is the best and highest. The line furthest to the left of the graph is the turbos surge limit. The turbo cannot operate before this line and will roughly follow it until the waste gate kicks in. How do you determine a turbos efficiency? The laws of thermodynamics say air being compressed to a certain pressure ratio should heat up to a certain temperature. That’s in an absolute non existing environment, because the air is affected by outside variables. Air flowing through a turbo is heated even more from the hot metal its inside of and turbulence from the blades. A turbo is put through an extensive test when made to measure the actual heat of the compressed air and compare it to what the laws of thermodynamics say it should actually be. This is the percentage you see on the graph; the actual percent of efficiency. The objective is to find a turbo that puts our little flow line, as close to the center as possible.

Step 5: Using the flow map

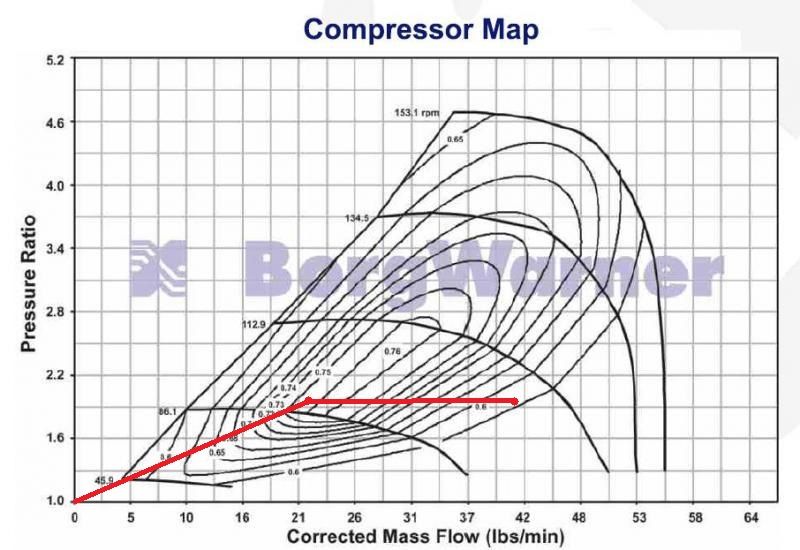

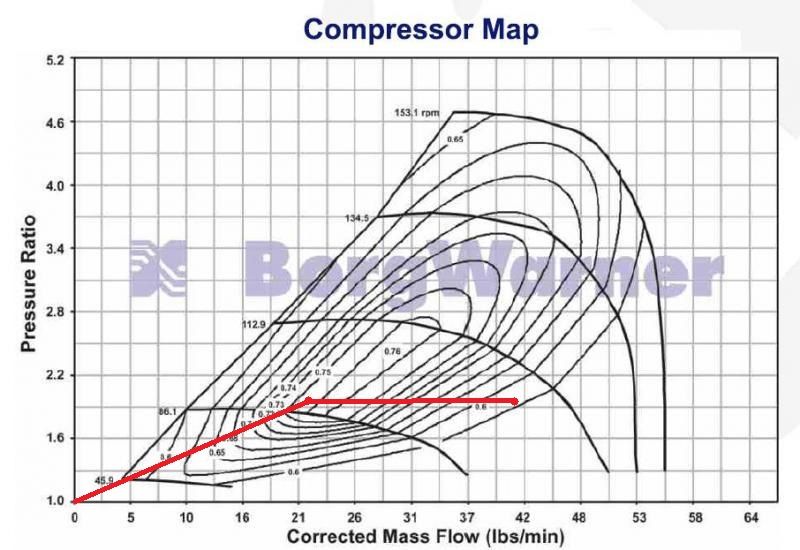

Using the flow map for the EFR 7064 I begin by taking my minimum flow dot which is 21.3 at a pressure ratio of 2, and place it on the graph. Then take the high flow dot, and do the same and draw a line between the two. This represents how the turbo will flow at 14.7lbs of boost from 4000RPM to 7800RPM. Lastly draw a line from the lower dot directly to the left bottom of the graph. This represents the path the turbo will take until the waste gate kicks in. These ARE NOT EXACT. Reason being the spring in a waste gate will start releasing pressure before it hits max boost because of pressure building behind it and that in turn cause mild lag. But that’s beside the point right now. This is theory we’re working with. It is best to make sure that the line stays in front of the surge limit; anyway the graph should look like this:

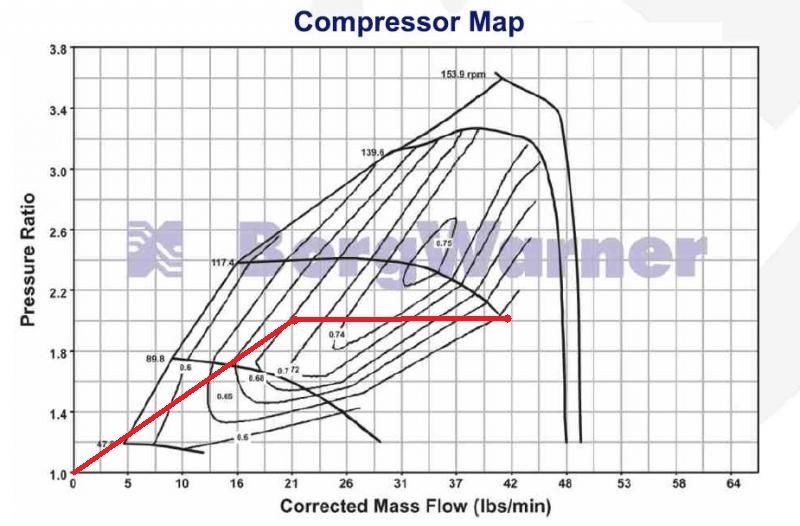

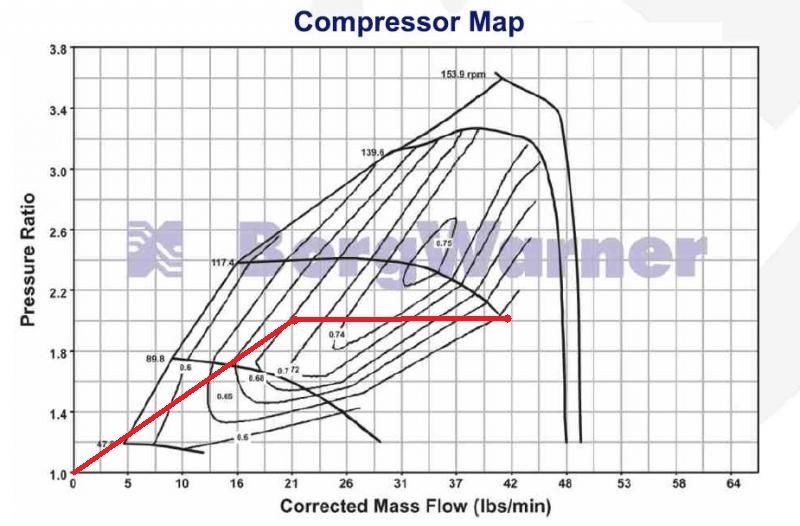

So according to this graph, this turbo this turbo is basically perfect. This turbo actually spools incredibly quickly! If I am cruising as low as 3000 RPM and go wide open throttle the turbo should still spool fairly quickly. This is also at the lower end of the efficiency range and so there is plenty of room to turn up the pressure if I so choose. This way the turbo isn’t strained at all and stay in the low turbine speed range. I have gone ahead and plotted our data onto the next turbo, the EFR 6758.

This turbo is right at the efficiency range, except the engine revs up a little too high. This is perfectly fine and greatly suitable for a daily driver. It doesn’t however leave any room for upgrading cams and stretching the power band out anymore. If I were to leave my engine as is and just run this turbo, it would be the optimum choice. This will also spool quite a bit earlier than the EFR 7064. This turbo will create more heat and not last as long because it is spinning at about 130,000RPM vs the bigger one spinning at around 100,000RPM. The decision rest on whether I plan to go bigger later, or have extremely good low end response.

So you’ve done some research and you’ve found a few turbos where your flow line is in a great location on the map, how do you decide? For starters, your final decision should be based on the following: which is more reliable, which is more available, price, and preference. Those are my critiques in the order I would use.

Other useful information.

This is how A/R ratio works. Area is area of the turbine scroll. Radius is the distance from the center of the turbine to the center of the turbine area. A diagram makes it slightly easier to understand.

As you come closer to the smaller part of the scroll and the area decreases, the radius also decreases, therefore the A/R ratio stays the same. For two turbos to put out the same CFM, the smaller turbine outlet will have higher exit velocity and a higher turbine speed. Consider a turbo with a 2.5 inch outlet bore, the given turbo will have an RPM of 80,000 at a certain CFM. Now for a turbo with a 2 inch outlet bore to flow the same CFM, the turbine wheel will be moving at 125,000 (not considering Bernoulli’s factors). Now obviously the lower turbine speed, the better it is on the turbo. The lower A/R ratio, lets say 0.75 will create a strong low engine speed response, but too low can cause a jumpy spool and fading power in the upper RPMs. Now a higher A/R ratio of say 1.5 will create a slower turbine response, but create more power. Too high of an A/R ratio can cause a sluggish spool and the turbo may not even have enough manifold pressure and velocity to create boost. A good spooling turbo that creates good power will generally have an A/R between 1.1 and 1.3. It all depends on your preference of power band and spool time.

There are also some turbos with a split turbine housing. This is a very good improvement for 4 cylinder engines especially. We’ll call an exhaust pulse a “putt”. So in this case the turbo gets a putt at every 360 degrees of crank rotation. There are 4 cylinders, two fire at every 360 degrees. Moving exhaust pulses can affect each other and with there only being two puts in a 720 degree rotation (4 cycle engine), the turbo will need all the help it can get and a split housing will separate pulses allowing for better momentum. This wouldn’t be so useful on a single turbo V8 because there will be a putt every 90 degrees of rotation so the turbo will have a good response.

Not many of us tuners here have to worry about a twin turbo setup, but I might as well write about it. Twin turbos do not reduce lag enough to be a concern. If you have two smaller turbos instead of one big turbo, smaller turbos spool faster than a big turbo, but you are also cutting the pulses in half, therefore having half the power to each turbo. The benefits of a twin turbo design are usually only beneficial in engines with two exhaust banks, or sequential turbos when boost is needed in a large power band; as in an RX-7 TT. A smaller turbo runs at low speeds and then the larger turbo kicks in at higher RPMs. Same thing with a RB26DETT, they wrap up to like 10,000 in some cases. There is also exducer flow efficiency, two turbos with an exducer bore of 2.25 inches will always flow better than one turbo of 3, or even 4 inches. Smaller turbos also mean that boost spikes and turbine wheel speeds are easier to control because each turbo is compressing air a smaller amount than a large turbo would. Lastly and what I believe to be the best reason is that an engine will create a certain amount of heat, absorbed into the turbo/s housing and a certain amount of heat must be created to produce a certain amount of boost. So one turbo will absorb all the heat to produce boost, two turbos will operate at a much lower temperature, sometimes half the temperature, to create the same amount of boost, therefore extending turbine and oil life.

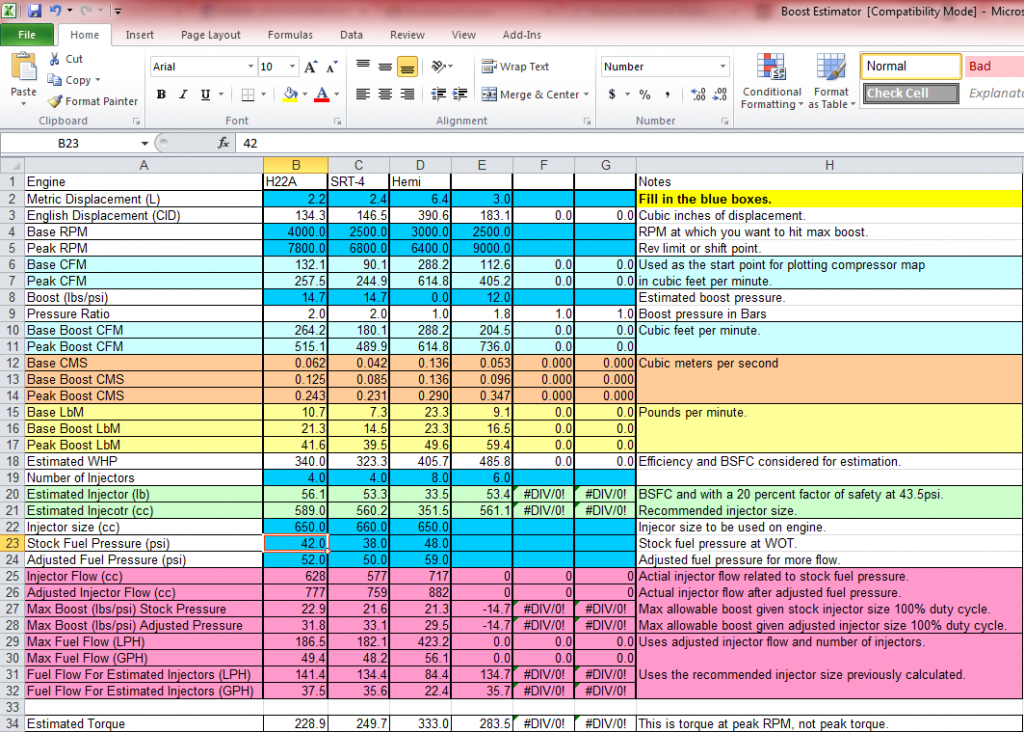

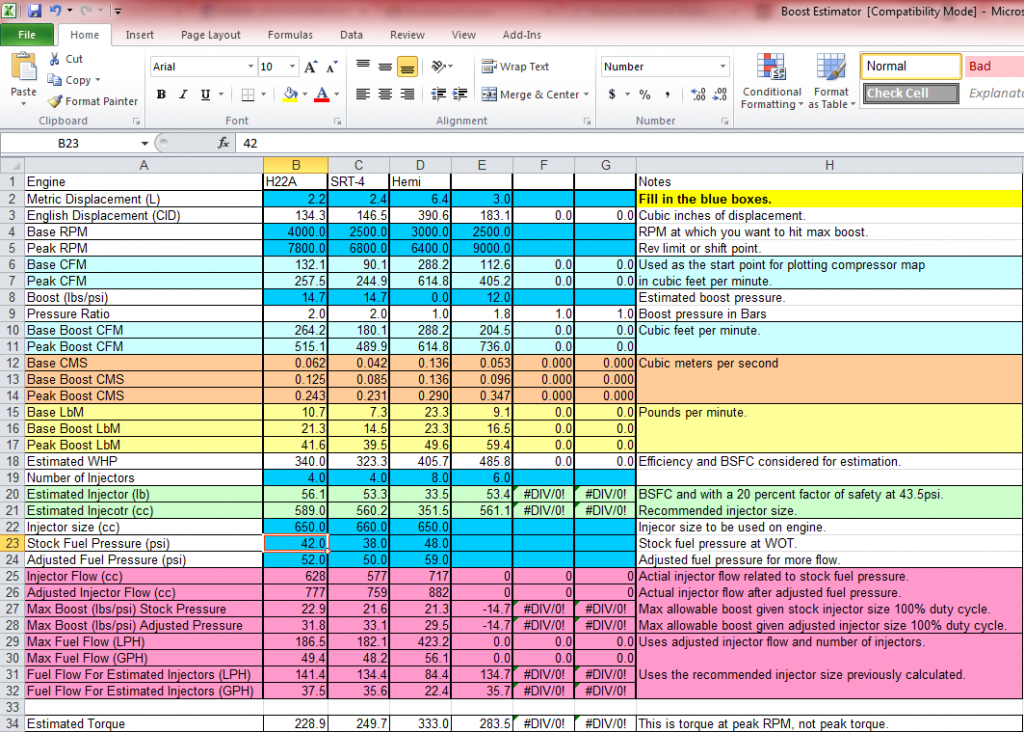

Here is a macro I designed to aid in the calculations. Just input the info in the blue specific to your application.

https://docs.google.com/file/d/0ByXA...it?usp=sharing

All fuel information is based off an engine that pumps air at an 85% efficiency and is also based of the well accepted relationship between CFM and BSFC. HP is not peak HP, it is HP at that RPM. It is also a low ball meaning actual HP of a well-designed system will be at least the same or greater. Remember this is an estimator to give an accurate idea of where your particular values sit. These CFM values are used to compare different compressor maps for your particular needs which is explained in the write ups.

Tools:

Boost Macro which you can get by providing me an email. I will try to update with a downloadable link.

Step One: Getting to know your engine.

Engine CFM (cubic feet per minute) is how much air flows through your engine in a stroke. To figure out how much air moves through your engine, follow this simple equation:

CFM = (CID x RPM x 0.5 x Ev)/1728

CID is cubic inch of displacement. 2L = 122, so to translate liters into CID just multiply Liter by 61 Ex: 1.6L x 61= 97.6CID

The 0.5 is used because only two pistons vacuum air at one point in time.

Ev is volumetric efficiency. It is the amount of air an engine draws in divided by the amount of air the engine should draw in a perfect environment. A well designed turbo engine will run at about 85%. If you have a flow meter hooked up to your engine you can measure the exact airflow at certain RPM’s and calculate the exact Ev at that RPM, this will make the calculations much more exact.

1728 is used to translate cubic INCHES into cubic FEET.

Example:

I will use my 2.2L H22A engine as a baseline and I want to pull power at 7800 RPM.

CID = 2.2L x 61CID/L = 134.2 CID

CFM = (134.2 x 7800 x 0.5 x 0.85)1728= 257.5 CFM

This means that my engine, at 7800 RPM, is pulling 257.5 cubic feet per minute.

Step 2: Understand pressure ratios.

1 Bar=14.7psi of boost. Atmospheric pressure is on average, 1 Bar. Boost is pressure above atmospheric pressure. For example, I want to increase my engines input by 14.7psi for simplicity.

Now we must find the pressure ratio.

PR = (14.7 + boost [in psi])/14.7. (14.7 + 14.7)/14.7 = 2. This means I will be running exactly 2 Bars of boost of absolute pressure, which is actually 1 Bar of Boost at atmospheric pressure.

Step 3: Apply boost to engine

257.5 CFM x 2 = 515 CFM at 14.7psi of boost. A good turbo setup for great power and good daily driving the turbo should spool up at roughly over the freeway cruising speed to ensure the engine won’t boost unless you want it to. For my engine it would be desired for the turbo to spool around 4000RPM. This will be Boost Threshold. Now I must find the flow of air at my boost threshold.

((134.2 x 4000 x 0.5 x 0.85)/1728) x 2) = 264 CFM.

Next is to find a turbo that will flow 264CFM to 515CFM at a pressure ratio of 2. Here is where the Turbo Flow Map becomes useful. For the comparison I will use Borg Warner EFR turbos since that is what I am actually looking into using. Full-race.com is a great supplier of the EFR turbos and they can be found here http://www.full-race.com/store/efr-turbos/. Conveniently they also supply the compressor maps in both English and metric. I will use English units in lbs of air.

To convert CFM to lbs, multiple CFM x .0807.

Base boost lbs = 264 x .0807 = 21.3lbs

Peak boost lbs = 515 x .0807 = 41.6lbs

Step 4: How to read a turbo flow map.

Borg Warner EFR 7064 Turbo Flow Map

This is a webpage that I found to have flow maps for the most popular/common turbos out there. Luckily it also has two conversion tables to help with converting airflow, pressure, and even approximating HP!

http://www.rbracing-rsr.com/turbotech.html

A turbo flow map show a turbos efficiency for a certain flow of air across a range of pressure ratios. They also show a few lines from left to right that represent how fast the turbo wheel is spinning. The “bubble” looking lines are efficiency ranges. The middle is the best and highest. The line furthest to the left of the graph is the turbos surge limit. The turbo cannot operate before this line and will roughly follow it until the waste gate kicks in. How do you determine a turbos efficiency? The laws of thermodynamics say air being compressed to a certain pressure ratio should heat up to a certain temperature. That’s in an absolute non existing environment, because the air is affected by outside variables. Air flowing through a turbo is heated even more from the hot metal its inside of and turbulence from the blades. A turbo is put through an extensive test when made to measure the actual heat of the compressed air and compare it to what the laws of thermodynamics say it should actually be. This is the percentage you see on the graph; the actual percent of efficiency. The objective is to find a turbo that puts our little flow line, as close to the center as possible.

Step 5: Using the flow map

Using the flow map for the EFR 7064 I begin by taking my minimum flow dot which is 21.3 at a pressure ratio of 2, and place it on the graph. Then take the high flow dot, and do the same and draw a line between the two. This represents how the turbo will flow at 14.7lbs of boost from 4000RPM to 7800RPM. Lastly draw a line from the lower dot directly to the left bottom of the graph. This represents the path the turbo will take until the waste gate kicks in. These ARE NOT EXACT. Reason being the spring in a waste gate will start releasing pressure before it hits max boost because of pressure building behind it and that in turn cause mild lag. But that’s beside the point right now. This is theory we’re working with. It is best to make sure that the line stays in front of the surge limit; anyway the graph should look like this:

So according to this graph, this turbo this turbo is basically perfect. This turbo actually spools incredibly quickly! If I am cruising as low as 3000 RPM and go wide open throttle the turbo should still spool fairly quickly. This is also at the lower end of the efficiency range and so there is plenty of room to turn up the pressure if I so choose. This way the turbo isn’t strained at all and stay in the low turbine speed range. I have gone ahead and plotted our data onto the next turbo, the EFR 6758.

This turbo is right at the efficiency range, except the engine revs up a little too high. This is perfectly fine and greatly suitable for a daily driver. It doesn’t however leave any room for upgrading cams and stretching the power band out anymore. If I were to leave my engine as is and just run this turbo, it would be the optimum choice. This will also spool quite a bit earlier than the EFR 7064. This turbo will create more heat and not last as long because it is spinning at about 130,000RPM vs the bigger one spinning at around 100,000RPM. The decision rest on whether I plan to go bigger later, or have extremely good low end response.

So you’ve done some research and you’ve found a few turbos where your flow line is in a great location on the map, how do you decide? For starters, your final decision should be based on the following: which is more reliable, which is more available, price, and preference. Those are my critiques in the order I would use.

Other useful information.

This is how A/R ratio works. Area is area of the turbine scroll. Radius is the distance from the center of the turbine to the center of the turbine area. A diagram makes it slightly easier to understand.

As you come closer to the smaller part of the scroll and the area decreases, the radius also decreases, therefore the A/R ratio stays the same. For two turbos to put out the same CFM, the smaller turbine outlet will have higher exit velocity and a higher turbine speed. Consider a turbo with a 2.5 inch outlet bore, the given turbo will have an RPM of 80,000 at a certain CFM. Now for a turbo with a 2 inch outlet bore to flow the same CFM, the turbine wheel will be moving at 125,000 (not considering Bernoulli’s factors). Now obviously the lower turbine speed, the better it is on the turbo. The lower A/R ratio, lets say 0.75 will create a strong low engine speed response, but too low can cause a jumpy spool and fading power in the upper RPMs. Now a higher A/R ratio of say 1.5 will create a slower turbine response, but create more power. Too high of an A/R ratio can cause a sluggish spool and the turbo may not even have enough manifold pressure and velocity to create boost. A good spooling turbo that creates good power will generally have an A/R between 1.1 and 1.3. It all depends on your preference of power band and spool time.

There are also some turbos with a split turbine housing. This is a very good improvement for 4 cylinder engines especially. We’ll call an exhaust pulse a “putt”. So in this case the turbo gets a putt at every 360 degrees of crank rotation. There are 4 cylinders, two fire at every 360 degrees. Moving exhaust pulses can affect each other and with there only being two puts in a 720 degree rotation (4 cycle engine), the turbo will need all the help it can get and a split housing will separate pulses allowing for better momentum. This wouldn’t be so useful on a single turbo V8 because there will be a putt every 90 degrees of rotation so the turbo will have a good response.

Not many of us tuners here have to worry about a twin turbo setup, but I might as well write about it. Twin turbos do not reduce lag enough to be a concern. If you have two smaller turbos instead of one big turbo, smaller turbos spool faster than a big turbo, but you are also cutting the pulses in half, therefore having half the power to each turbo. The benefits of a twin turbo design are usually only beneficial in engines with two exhaust banks, or sequential turbos when boost is needed in a large power band; as in an RX-7 TT. A smaller turbo runs at low speeds and then the larger turbo kicks in at higher RPMs. Same thing with a RB26DETT, they wrap up to like 10,000 in some cases. There is also exducer flow efficiency, two turbos with an exducer bore of 2.25 inches will always flow better than one turbo of 3, or even 4 inches. Smaller turbos also mean that boost spikes and turbine wheel speeds are easier to control because each turbo is compressing air a smaller amount than a large turbo would. Lastly and what I believe to be the best reason is that an engine will create a certain amount of heat, absorbed into the turbo/s housing and a certain amount of heat must be created to produce a certain amount of boost. So one turbo will absorb all the heat to produce boost, two turbos will operate at a much lower temperature, sometimes half the temperature, to create the same amount of boost, therefore extending turbine and oil life.

Here is a macro I designed to aid in the calculations. Just input the info in the blue specific to your application.

https://docs.google.com/file/d/0ByXA...it?usp=sharing

All fuel information is based off an engine that pumps air at an 85% efficiency and is also based of the well accepted relationship between CFM and BSFC. HP is not peak HP, it is HP at that RPM. It is also a low ball meaning actual HP of a well-designed system will be at least the same or greater. Remember this is an estimator to give an accurate idea of where your particular values sit. These CFM values are used to compare different compressor maps for your particular needs which is explained in the write ups.

rediculously in depth REP FOR YOU

rediculously in depth REP FOR YOU

Comment