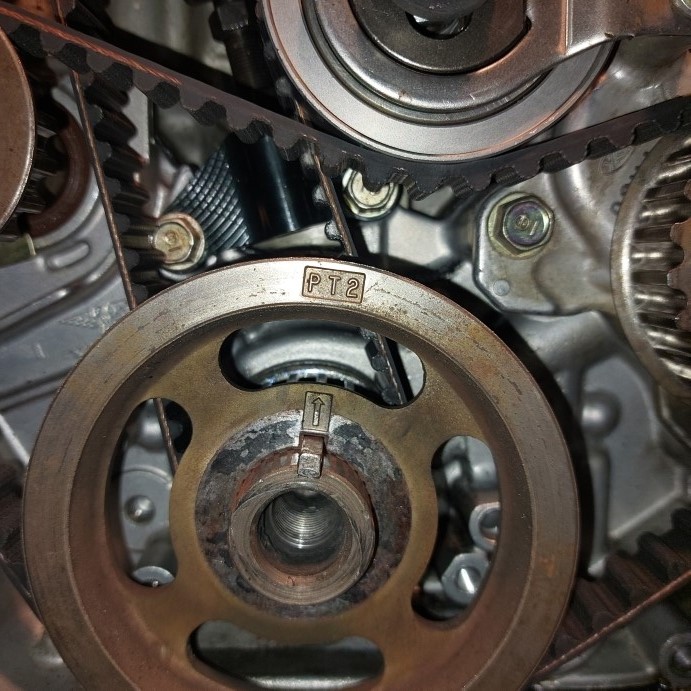

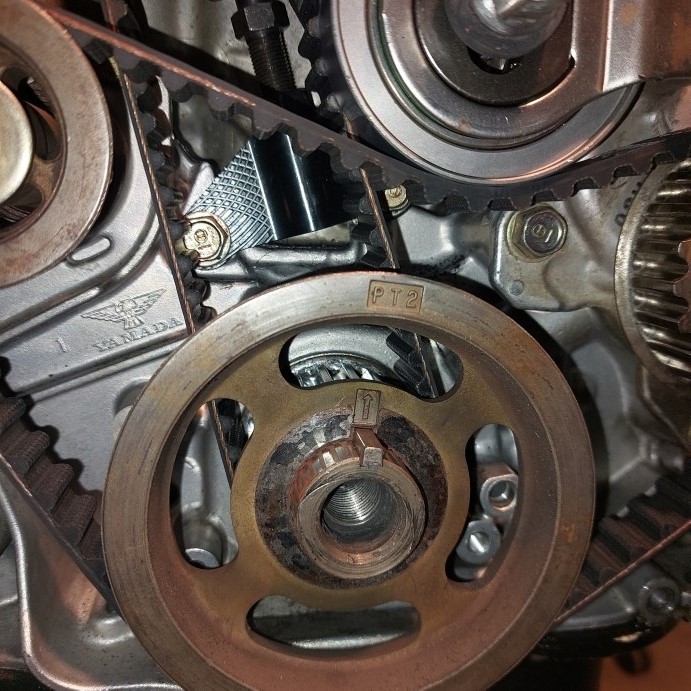

1993 honda accord LX, having trouble installing the crankshaft sprocket back on with key

I admit I had a problem taking it off. I had to use an extension over the key. And lightly tap on it with a hammer. And it slid right off easily (not the first time, because I didn't notice). I could take the key off really easily, and the sprocket slid off really easily.

So imagine my confusion when I go to install it. I put the key on first. And then I put the sprocket back on, and it just doesn't slide easily. I thought it was the key. So I tried it without the key, and it had the same effect. I try to push up and down with my hands.

So now I get some advice, just use a wooden hammer. I don't have one. About the third or fourth tool I don't have. So when I go to buy a tool, it doesn't work anyway.

Anyway, I try to use a block of wood. Unfortunately, I only have long pieces of wood. That did help, I did get it on there somewhat. It's moving on there with the key. But the sprocket is now more flush with the shaft. So I can't smack it on there with full force because the shaft is in the way. I have to pick a side. But my confusion, does the key have to be perfectly flush with where it sits? Because even if I do manage to get it on there, I think the key is pushed in there just a tad. What's unreal about this job, I paid for a timing belt video. The 1997 Accord is completely different. It's kind of useless. Although it does have tips. Anyway, he just first puts the key on, and he just, with ease and with his hands, slides the sprocket on there like it's nothing. Maybe it's just my luck when it comes to cars, I just get stuck on the silly stuff?

But anyway, how perfectly aligned does that key have to be? Is there any tips on this? Maybe I should go get a puller and pull the whole thing off. And maybe try to install without the key. And then put the key in there the way I want?

I admit I had a problem taking it off. I had to use an extension over the key. And lightly tap on it with a hammer. And it slid right off easily (not the first time, because I didn't notice). I could take the key off really easily, and the sprocket slid off really easily.

So imagine my confusion when I go to install it. I put the key on first. And then I put the sprocket back on, and it just doesn't slide easily. I thought it was the key. So I tried it without the key, and it had the same effect. I try to push up and down with my hands.

So now I get some advice, just use a wooden hammer. I don't have one. About the third or fourth tool I don't have. So when I go to buy a tool, it doesn't work anyway.

Anyway, I try to use a block of wood. Unfortunately, I only have long pieces of wood. That did help, I did get it on there somewhat. It's moving on there with the key. But the sprocket is now more flush with the shaft. So I can't smack it on there with full force because the shaft is in the way. I have to pick a side. But my confusion, does the key have to be perfectly flush with where it sits? Because even if I do manage to get it on there, I think the key is pushed in there just a tad. What's unreal about this job, I paid for a timing belt video. The 1997 Accord is completely different. It's kind of useless. Although it does have tips. Anyway, he just first puts the key on, and he just, with ease and with his hands, slides the sprocket on there like it's nothing. Maybe it's just my luck when it comes to cars, I just get stuck on the silly stuff?

But anyway, how perfectly aligned does that key have to be? Is there any tips on this? Maybe I should go get a puller and pull the whole thing off. And maybe try to install without the key. And then put the key in there the way I want?

Comment