MANUFACTURER'S SUGGESTED SCHEDULED MAINTENANCE

For 1990-94 vehicles, the manufacturer recommends camshaft and balance shaft belts be replaced at 90,000 miles. For 1995-96 vehicles, the manufacturer recommends the belt be replaced at 90,000 miles for normal service or 60,000 miles for severe service.

For 1997 vehicles, normal replacement interval is at 105,000 miles or 84 months. Replace at 60,000 miles if car is regularly driven in extreme temperatures (over 110 degrees F, or under -20 degrees F).

CAUTION: This application is an interference engine. Do not rotate camshaft or crankshaft when timing belt is removed, or engine damage may occur. Inspect timing belt & balance shaft belt tensioner pullies for free-rotation, no seizure/rough-rotation. Otherwise, replace units.

REMOVAL & INSTALLATION - TIMING & BALANCE SHAFT BELTS

Removal

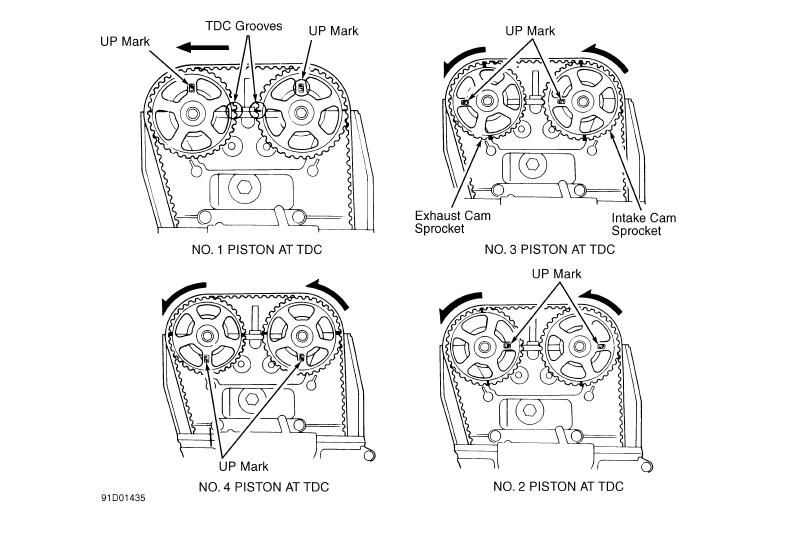

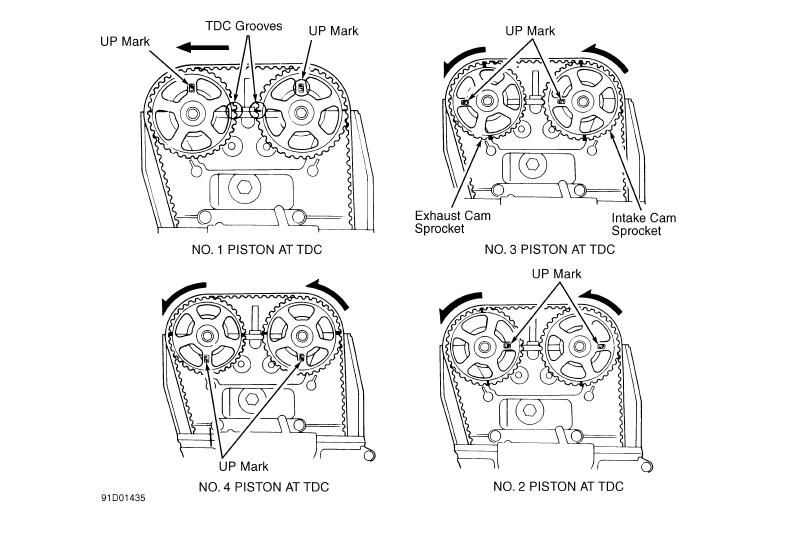

1. Disconnect negative battery cable. Position crankshaft with cylinder No. 1 at TDC of compression stroke. See Fig. 1 , Fig. 2 or Fig. 3. Disconnect battery negative cable. Remove splash shield. Remove cruise control actuator, leaving cable connected. Remove power steering pump, leaving hoses connected.

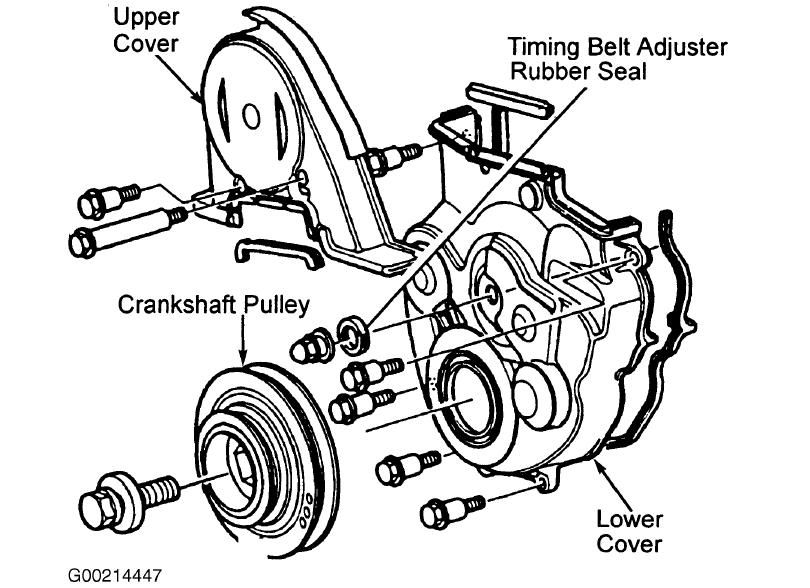

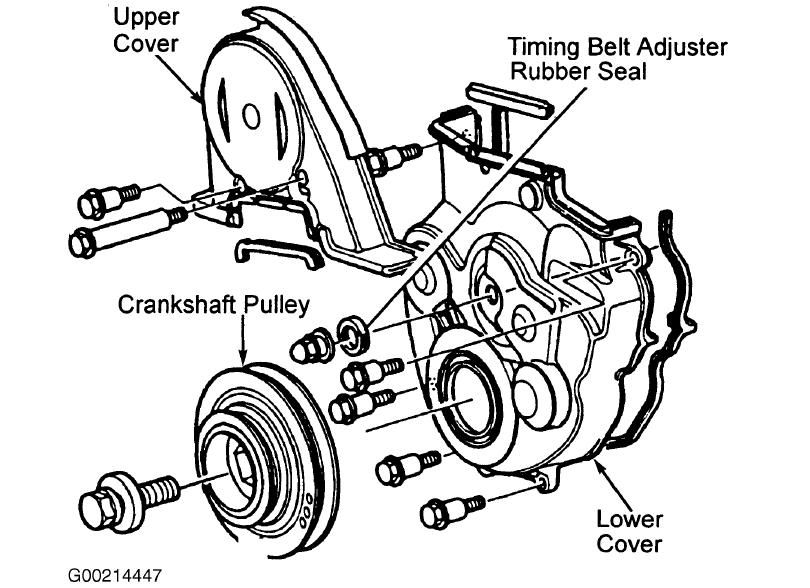

2. Disconnect alternator wiring. Remove wiring harness from valve cover. Remove alternator and A/C belts (if equipped). Remove valve cover and upper timing belt cover. Remove side engine mount. Remove engine oil dipstick and tube. Remove crankshaft pulley. See Fig. 4 .

3. Support engine. Remove 2 rear bolts from engine center support beam. Lower engine enough to permit removal of lower timing belt cover. Remove rubber seal from belt tension adjuster nut. Remove lower timing belt cover.

4. CAUTION: DO NOT rotate crankshaft or camshaft when removing timing belts.

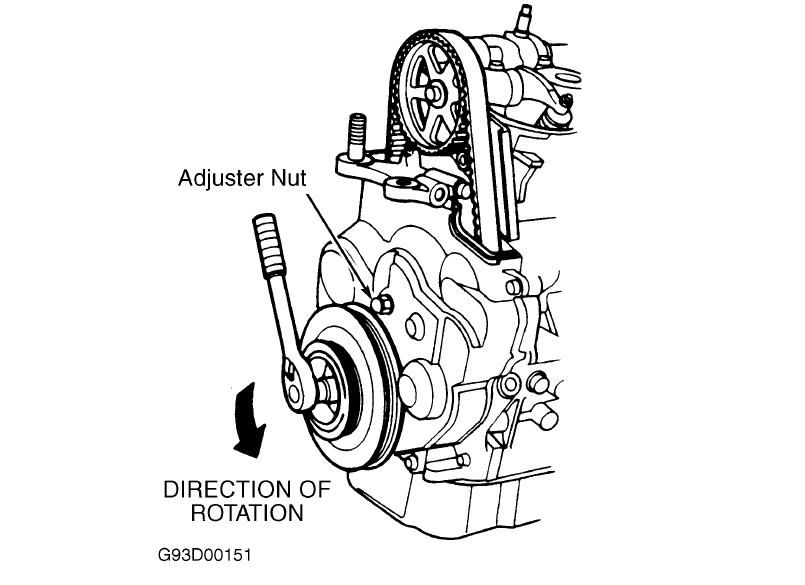

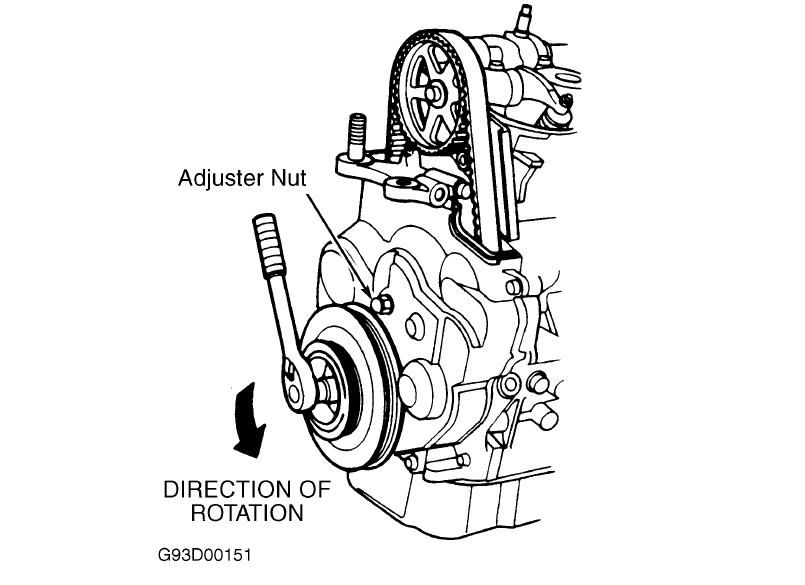

Lock timing belt adjuster arm into position by installing one lower cover retaining bolt. Loosen belt tension adjuster bolt. See Fig. 5 . Push belt tensioner to release tension from belt. Tighten adjuster bolt. Remove balance shaft and camshaft timing belts.

Fig. 1: Positioning Camshaft Sprocket for Valve Adjustment (2.2L SOHC - Accord)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 2: Positioning Camshaft Sprocket for Valve Adjustment (2.2L SOHC - Prelude)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 3: Positioning Camshaft Sprockets for Valve Adjustment (Prelude 2.3L DOHC)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 4: Removing & Installing Crankshaft Pulley (Typical)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 5: Locating Timing Belt Adjuster Nut (Typical)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Inspection

With belt or belt covers removed, inspect belts for wear, cracks, or oil soaking. Inspect belt teeth for wear. Replace belt if worn, oil soaked, or cracked.

Installation

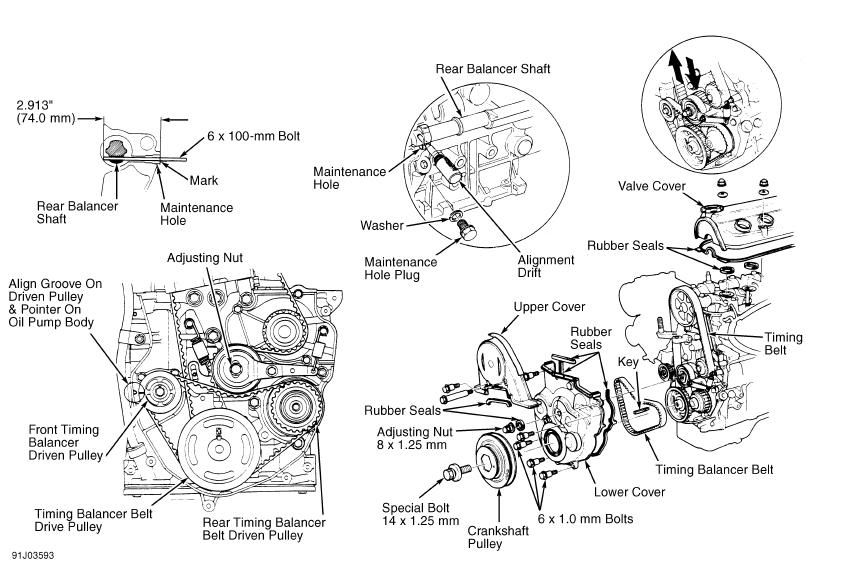

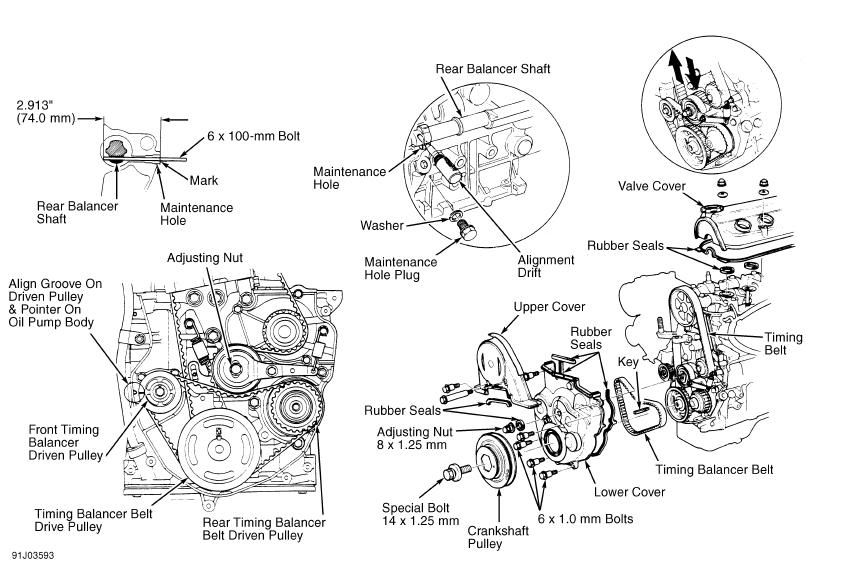

1. Align White mark on flywheel or drive plate (flexplate) with pointer on block. Ensure camshaft(s) is at TDC for No. 1 cylinder. See Fig. 1 , Fig. 2 or Fig. 3 . Install camshaft timing belt. See Fig. 6. Align rear timing balance shaft belt pulley by inserting a 6 x 100 mm bolt 2.9" (74 mm) into alignment access hole. Align groove on front balance shaft pulley with pointer on oil pump body. See Fig. 7 .

2. Adjust timing belt tension by rotating crankshaft counterclockwise until No. 1 piston is at TDC of compression stroke. Loosen, but do not remove, timing belt adjustment bolt. Rotate crankshaft counterclockwise 3 teeth on camshaft pulley to create tension on timing belt. Tighten adjustment bolt to specification. See TORQUE SPECIFICATIONS .

3. Reverse removal procedure to complete installation. Tighten crankshaft pulley bolt to specification. See TORQUE SPECIFICATIONS . Adjust drive belts to proper tension.

Fig. 6: Removing & Installing Timing & Balance Shaft Belts

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 7: Aligning Balancer Belt Driven Pulley

CB7 Timing Belt Procdure

CB7 Torque Specs

CB7 Tune-Up Specs

CB7 Fluid Capacities

For 1990-94 vehicles, the manufacturer recommends camshaft and balance shaft belts be replaced at 90,000 miles. For 1995-96 vehicles, the manufacturer recommends the belt be replaced at 90,000 miles for normal service or 60,000 miles for severe service.

For 1997 vehicles, normal replacement interval is at 105,000 miles or 84 months. Replace at 60,000 miles if car is regularly driven in extreme temperatures (over 110 degrees F, or under -20 degrees F).

CAUTION: This application is an interference engine. Do not rotate camshaft or crankshaft when timing belt is removed, or engine damage may occur. Inspect timing belt & balance shaft belt tensioner pullies for free-rotation, no seizure/rough-rotation. Otherwise, replace units.

REMOVAL & INSTALLATION - TIMING & BALANCE SHAFT BELTS

Removal

1. Disconnect negative battery cable. Position crankshaft with cylinder No. 1 at TDC of compression stroke. See Fig. 1 , Fig. 2 or Fig. 3. Disconnect battery negative cable. Remove splash shield. Remove cruise control actuator, leaving cable connected. Remove power steering pump, leaving hoses connected.

2. Disconnect alternator wiring. Remove wiring harness from valve cover. Remove alternator and A/C belts (if equipped). Remove valve cover and upper timing belt cover. Remove side engine mount. Remove engine oil dipstick and tube. Remove crankshaft pulley. See Fig. 4 .

3. Support engine. Remove 2 rear bolts from engine center support beam. Lower engine enough to permit removal of lower timing belt cover. Remove rubber seal from belt tension adjuster nut. Remove lower timing belt cover.

4. CAUTION: DO NOT rotate crankshaft or camshaft when removing timing belts.

Lock timing belt adjuster arm into position by installing one lower cover retaining bolt. Loosen belt tension adjuster bolt. See Fig. 5 . Push belt tensioner to release tension from belt. Tighten adjuster bolt. Remove balance shaft and camshaft timing belts.

Fig. 1: Positioning Camshaft Sprocket for Valve Adjustment (2.2L SOHC - Accord)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 2: Positioning Camshaft Sprocket for Valve Adjustment (2.2L SOHC - Prelude)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 3: Positioning Camshaft Sprockets for Valve Adjustment (Prelude 2.3L DOHC)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 4: Removing & Installing Crankshaft Pulley (Typical)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 5: Locating Timing Belt Adjuster Nut (Typical)

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Inspection

With belt or belt covers removed, inspect belts for wear, cracks, or oil soaking. Inspect belt teeth for wear. Replace belt if worn, oil soaked, or cracked.

Installation

1. Align White mark on flywheel or drive plate (flexplate) with pointer on block. Ensure camshaft(s) is at TDC for No. 1 cylinder. See Fig. 1 , Fig. 2 or Fig. 3 . Install camshaft timing belt. See Fig. 6. Align rear timing balance shaft belt pulley by inserting a 6 x 100 mm bolt 2.9" (74 mm) into alignment access hole. Align groove on front balance shaft pulley with pointer on oil pump body. See Fig. 7 .

2. Adjust timing belt tension by rotating crankshaft counterclockwise until No. 1 piston is at TDC of compression stroke. Loosen, but do not remove, timing belt adjustment bolt. Rotate crankshaft counterclockwise 3 teeth on camshaft pulley to create tension on timing belt. Tighten adjustment bolt to specification. See TORQUE SPECIFICATIONS .

3. Reverse removal procedure to complete installation. Tighten crankshaft pulley bolt to specification. See TORQUE SPECIFICATIONS . Adjust drive belts to proper tension.

Fig. 6: Removing & Installing Timing & Balance Shaft Belts

Courtesy of AMERICAN HONDA MOTOR CO., INC.

Fig. 7: Aligning Balancer Belt Driven Pulley

TORQUE SPECIFICATIONS

Application Ft. Lbs. (N.m)

A/C Compressor Bracket Bolt 37 (50)

Alternator Bracket Adjuster Bolt 16 (22)

Alternator Bracket Bolt 33 (45)

Balance Shaft Pulley Bolt 22 (30)

Camshaft Pulley Bolt

2.2L DOHC 37 (51)

2.2L SOHC & 2.3L 27 (37)

Crankshaft Pulley Bolt 184 (250)

Power Steering Belt Adjuster Nut 11 (15)

Power Steering Pump Bracket Bolt 33 (45)

Power Steering Pump Mounting Bolt 16 (22)

Shift Cable Bracket Bolt 16 (22)

Timing Belt Tension Adjuster 33 (45)

INCH Lbs. (N.m)

Timing Belt Cover Bolt 108 (12)

Valve Cover Nut 108 (12)

Water Pump Bolt 108 (12)

Application Ft. Lbs. (N.m)

A/C Compressor Bracket Bolt 37 (50)

Alternator Bracket Adjuster Bolt 16 (22)

Alternator Bracket Bolt 33 (45)

Balance Shaft Pulley Bolt 22 (30)

Camshaft Pulley Bolt

2.2L DOHC 37 (51)

2.2L SOHC & 2.3L 27 (37)

Crankshaft Pulley Bolt 184 (250)

Power Steering Belt Adjuster Nut 11 (15)

Power Steering Pump Bracket Bolt 33 (45)

Power Steering Pump Mounting Bolt 16 (22)

Shift Cable Bracket Bolt 16 (22)

Timing Belt Tension Adjuster 33 (45)

INCH Lbs. (N.m)

Timing Belt Cover Bolt 108 (12)

Valve Cover Nut 108 (12)

Water Pump Bolt 108 (12)

CB7 Timing Belt Procdure

CB7 Torque Specs

CB7 Tune-Up Specs

CB7 Fluid Capacities

__

__

Comment