I am considering taking on an arduino powered TCU replacement project. It will not be fast or easy and I was just curious if anyone else had a leg up on open source hardware and software and would be willing to give it a run. This would be a programmable technical part that controls shift solenoids and reads speed and temp sensors and controls up shifts and down shifts, and with the touch of a button you can change your shift points to be more efficient or more powerful. I want to start only on the basics of it and start gathering components over the next few weeks, I'll have a lot of studying to do between now and then to be sure to cover all functions of the TCU and inputs/outputs based on schematic diagrams and shift control programs.

This will only work on OBD I cars as the TCU is separate from the ECU.

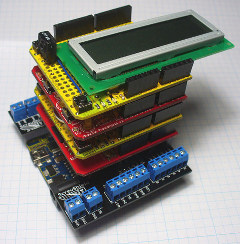

Just seeing who is interested in giving up more of their life to the CB7 and who can help with this type of deal. Also if the 16mhz arduino is too slow I can also use a teensy board or Exspresso ARM board.

Also can add an LCD screen for MPG and current gear and paddle shifting capabilities fairly cheap once the boards are working correctly.

Some extra reading:

http://www.yotatech.com/f131/custom-...-shift-247091/

http://www.yotatech.com/f2/paddle-sh...roject-245425/

https://forum.sparkfun.com/viewtopic.php?t=18756

http://arduino.cc/forum/index.php/topic,84997.0.html

http://arduino.cc/forum/index.php/to...html#msg729425

http://arduino.cc/forum/index.php?ac...;topic=69166.0

Basically I could buy a MegaShift from MegaSquirt and mod it too I guess.

This will only work on OBD I cars as the TCU is separate from the ECU.

Just seeing who is interested in giving up more of their life to the CB7 and who can help with this type of deal. Also if the 16mhz arduino is too slow I can also use a teensy board or Exspresso ARM board.

Also can add an LCD screen for MPG and current gear and paddle shifting capabilities fairly cheap once the boards are working correctly.

Some extra reading:

http://www.yotatech.com/f131/custom-...-shift-247091/

http://www.yotatech.com/f2/paddle-sh...roject-245425/

https://forum.sparkfun.com/viewtopic.php?t=18756

http://arduino.cc/forum/index.php/topic,84997.0.html

http://arduino.cc/forum/index.php/to...html#msg729425

http://arduino.cc/forum/index.php?ac...;topic=69166.0

Basically I could buy a MegaShift from MegaSquirt and mod it too I guess.

Projects like this and solving problems keep me from feeling like I'm wasting my time/talent.

Projects like this and solving problems keep me from feeling like I'm wasting my time/talent.

Comment