Originally posted by dj_ender

View Post

Announcement

Collapse

No announcement yet.

Its time for a rebuild.....But my CB will live again.

Collapse

X

-

Oh I did.Originally posted by eightyfour84 View PostHope you hit that horizontal egr passage port. When I hit mine with the hanger tons of carbon came out. I think a lot of ppl forget about that horizontal passageway.

Originally posted by Mishakol129Do not disrespect my intelligence. I am the smartest person I know : )

Originally posted by Mishakol129Do not disrespect my intelligence. I am the smartest person I know : )

Comment

-

Progress is good brony.

02 Crv

02 silverado Ex cab Z71, 2011 TRD 17" wheels, 245/80/17, ls1 cam, AFE intake, 3" catback, tuned by Larry at LSXperformance&pcm tuning driven daily.

92 Acura Legend colbalt blue LS Coupe, custom intake, custom vibrant 2.5 cat back, led cluster and high beams, 2016 Coyote GT 18x8 wheels 235/40/18.

Coming Soon Tein TSX coilovers.

Comment

-

First off, awesome thread! Excellent work with lots of clean (and in focus!) photos! This has inspired me to hit up the JY tomorrow and see if I can find a head or even a whole block to work on; I've only got two rides, and my bicycle tires are flat.

This has inspired me to hit up the JY tomorrow and see if I can find a head or even a whole block to work on; I've only got two rides, and my bicycle tires are flat.

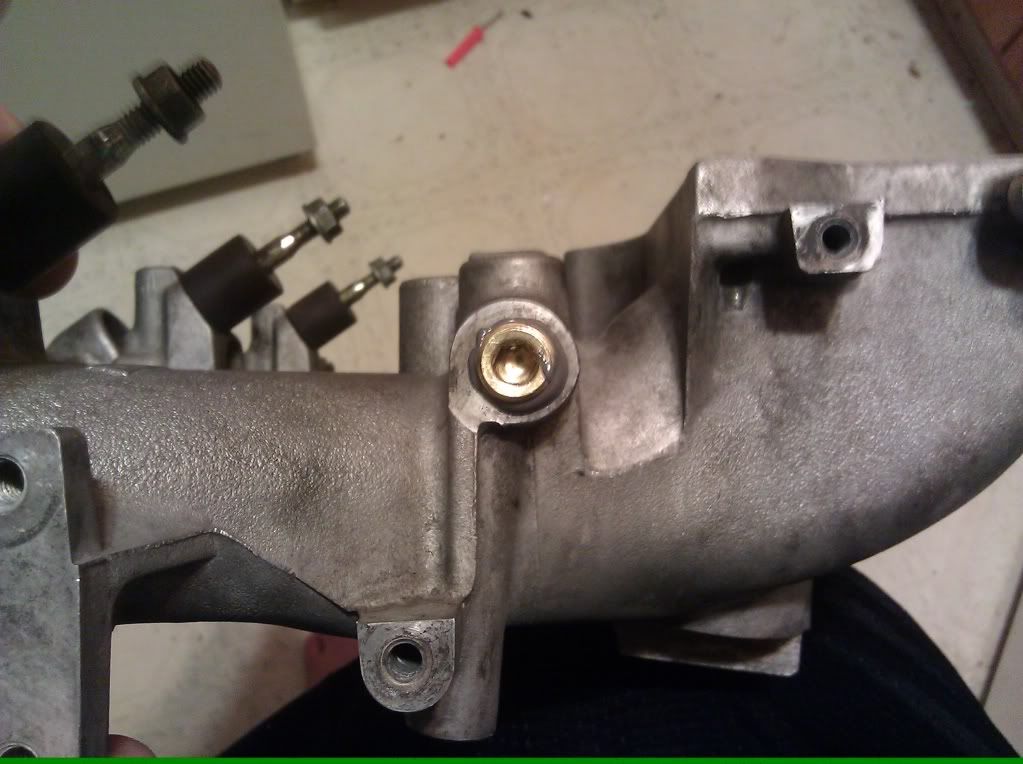

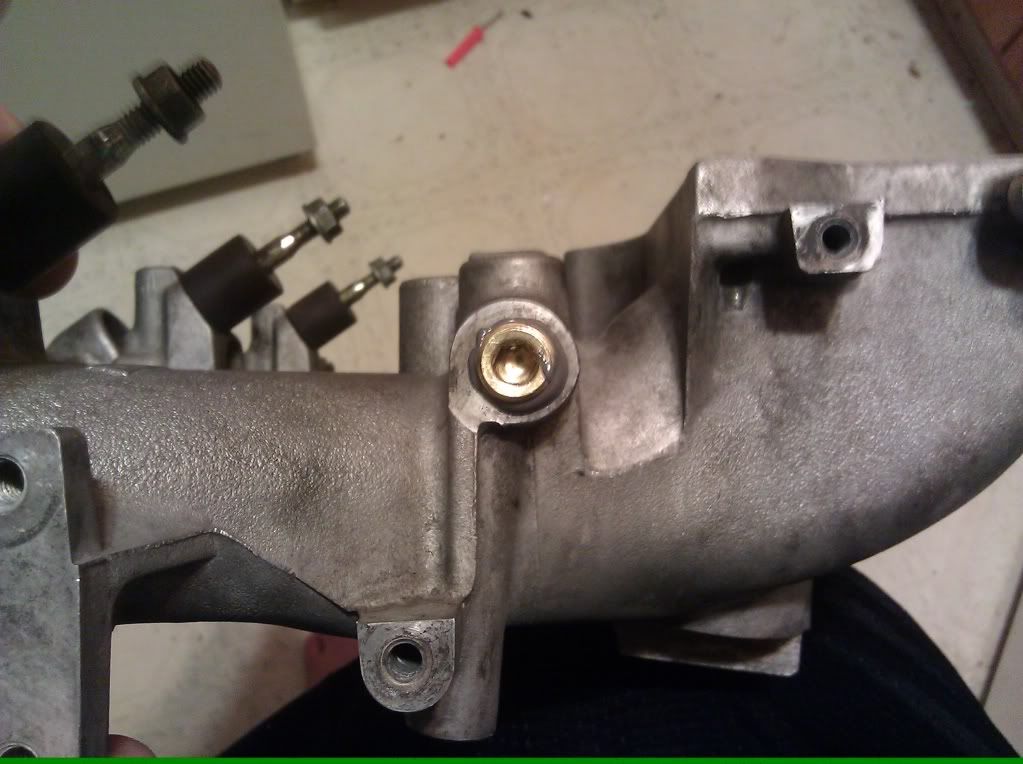

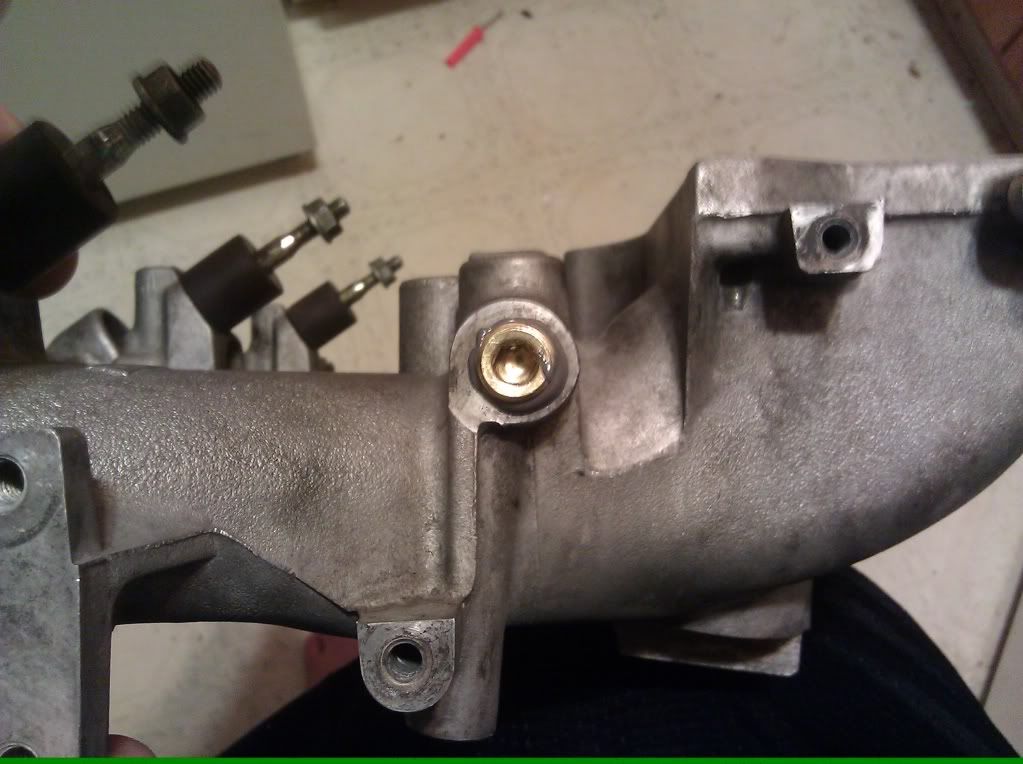

You might be aware that I recently did this to my intake as well. However, I followed wed3k's suggestion to tap with 1/2-20 UNF threads, and the only caps that I could find were hex headed SAE flare fitting plugs, made of steel. This means that they're hollow, have caps, and made of steel as opposed to the OEM choice of bronze, though I suspect the reason for bronze is because the OEM plugs were press fit.

I assume you used 1/2-20 UNF threads as well. Where did you find those bronze plugs?

On my intake, this plug looks to be bigger than the six on top, is that so? How did you remove this plug, and what did you drill and tap it with?

Keep up the good work and excellent documentation! I'm excited to see this back up and running.Last edited by reklipz; 11-04-2012, 06:16 AM.

Comment

-

Not dj_ender but that plug is indeed larger diameter than the top six. Honda didn't even have a replacement for it (thin steel cups for the top 6). I thought about drilling and tapping the egr ports to make it easier for future egr cleaning but didn't want to damage the manifold. For that plug because no replacement from Honda I put JB weld in the middle of the original plug where I drilled and reused it.Originally posted by reklipz View PostFirst off, awesome thread! Excellent work with lots of clean (and in focus!) photos! This has inspired me to hit up the JY tomorrow and see if I can find a head or even a whole block to work on; I've only got two rides, and my bicycle tires are flat.

This has inspired me to hit up the JY tomorrow and see if I can find a head or even a whole block to work on; I've only got two rides, and my bicycle tires are flat.

You might be aware that I recently did this to my intake as well. However, I followed wed3k's suggestion to tap with 1/2-20 UNF threads, and the only caps that I could find were hex headed SAE flare fitting plugs, made of steel. This means that they're hollow, have caps, and made of steel as opposed to the OEM choice of bronze, though I suspect the reason for bronze is because the OEM plugs were press fit.

I assume you used 1/2-20 UNF threads as well. Where did you find those bronze plugs?

On my intake, this plug looks to be bigger than the six on top, is that so? How did you remove this plug, and what did you drill and tap it with?

Keep up the good work and excellent documentation! I'm excited to see this back up and running.

Comment

-

Thanks!Originally posted by reklipz View Post

I assume you used 1/2-20 UNF threads as well. Where did you find those bronze plugs?

Yes, I did. At O' Reilly's. They are Edelman plugs part 226400

On my intake, this plug looks to be bigger than the six on top, is that so? How did you remove this plug, and what did you drill and tap it with?

The plug at the end is bigger. When I did this I didn't pay enough attention to the drill bit I was using, I ended up using a 1/2" rather than 7/16", so these plugs were not tapped. I screwed them into there holes to knock down the threads on the plug a little, removed them and covered the threads in JB Weld, lined the holes in the IM with JB Weld, and then tightened down. Thats why there is a perfect ring of JB Weld around the bolts.

Keep up the good work and excellent documentation! I'm excited to see this back up and running.

These particular plugs only came about because of my error, otherwise I could have used a smaller size.Originally posted by eightyfour84 View PostNot dj_ender but that plug is indeed larger diameter than the top six. Honda didn't even have a replacement for it (thin steel cups for the top 6). I thought about drilling and tapping the egr ports to make it easier for future egr cleaning but didn't want to damage the manifold. For that plug because no replacement from Honda I put JB weld in the middle of the original plug where I drilled and reused it.Originally posted by Mishakol129Do not disrespect my intelligence. I am the smartest person I know : )

Comment

-

First I want to apologize to dj_ender for posting offtopin in your thread.

reklipz, you do know that steel and alum don't play nice together, right? Have you ever heard of galvanic corrosion? They use brass because they are closer in the galvanic series.1993 SE Coupe MRT - 1992 LX Sedan MRT

93 Accord SE Bose Stereo MYTHS & FACTS - F22A* Power Plant Removal(UNDER CONSTRUCTION)

Comment

-

Parts came in this morning, I spent the day assembling the engine and removing the old header. I didnt take as many pictures during assembly as I did during disassembly, but here's a couple until tomorrow.

Last edited by dj_ender; 11-08-2012, 01:20 AM.Originally posted by Mishakol129Do not disrespect my intelligence. I am the smartest person I know : )

Last edited by dj_ender; 11-08-2012, 01:20 AM.Originally posted by Mishakol129Do not disrespect my intelligence. I am the smartest person I know : )

Comment

-

Funny you should mention that wildBill83. I had at one point a post all typed up explaining my concerns and my research, but then my phone decided to FUBAR and kill my post. I didn't want to bother to retype it.Originally posted by wildBill83 View PostFirst I want to apologize to dj_ender for posting offtopin in your thread.

reklipz, you do know that steel and alum don't play nice together, right? Have you ever heard of galvanic corrosion? They use brass because they are closer in the galvanic series.

Anyway, long story short, I am very aware, but thanks for bringing it up. According to the Wikipedia article on galvanic corrosion / galling, the galvanic potential between steel and aluminum is less than between brass and aluminum. Check the article and confirm or deny my findings: http://en.wikipedia.org/wiki/Galvanic_corrosion

I thought the same thing, that steel was bad, hence the reason I asked where dj_ender got the brass fittings. Then I read that article and was reassured I'm doing better than the OEM setup was. Please confirm/deny my findings!

Looking good dj_ender! Anxiously awaiting teardown/rebuild photos.

Comment

Comment