Originally posted by Shadow1

View Post

Originally posted by Bcozzi71

View Post

Originally posted by slick

View Post

Originally posted by pwrusr

View Post

This is ridiculous, I've been lagging too much. Update tomorrow, finals be damned.

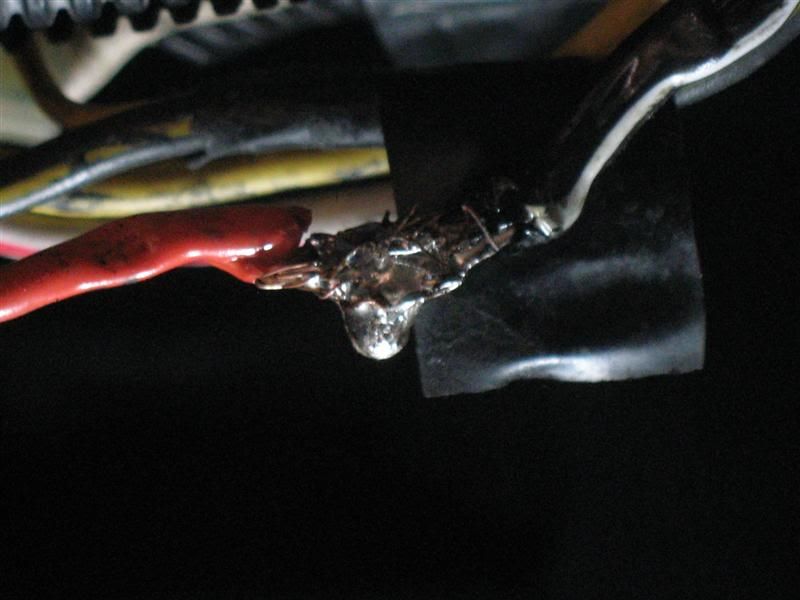

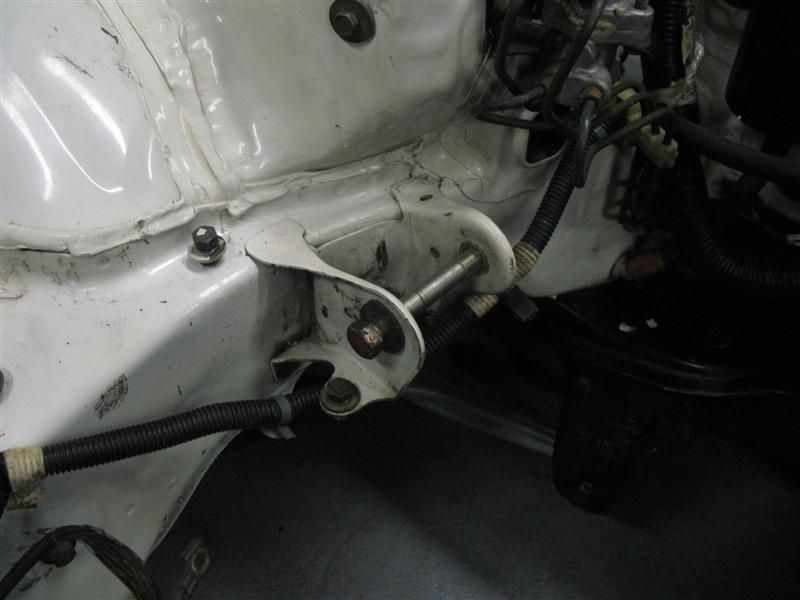

heres a pic. or at least the best pic i could find. someone else might have a better pic of it rolling too:

heres a pic. or at least the best pic i could find. someone else might have a better pic of it rolling too:

Comment