1992 Honda Accord EX

POWERTRAIN:

H22A Euro-R Swap

4 Piston CNC Cylinder Head P13 (milled .017)

Skunk2 Pro2 Cams

Skunk2 Pro Series Cam Gears

Supertech 93lb Valve Springs

Ferrea Valves

70-68mm Blox Throttle Body

BB4 Prelude AEM Intake

4-2-1 PLM Header

Greddy Evo 2 Exhaust system

Phearble ECU

HONDATA S300

HONDATA Coil Pack Retrofit

RSX Coils

Wire management

ABS Delete

Cruise Control Delete

Rosko Racing components (IACV / Fuel Rail adapter)

Heatshield Intake Manifold Gasket and TB Gasket

Balance Shaft Retainer

H23 Manual Tensioner Mod

Timing Belt / Balance Shaft serviced

Valve Clearances adjusted to spec

BB6 Cast aluminum oil pan/stiffener

Downstar Inc. Stainless Fasteners

Stock F22A6

DRIVETRAIN:

T2W4 Transaxle

Exedy Stage 1 Clutch

ACT Streetlite Flywheel

Hybrid Racing Detent Springs

FFC Solid Shift Linkage Bushings

MTEC Shift Springs

BIB Shift Linkage

Stock H2A5 Transaxle

*only needs a clutch...

Exedy Stage 1 Clutch

Stock Flywheel

CHASSIS:

Honda Remanufactured Steering Rack

HardRace steering rack mount bushings

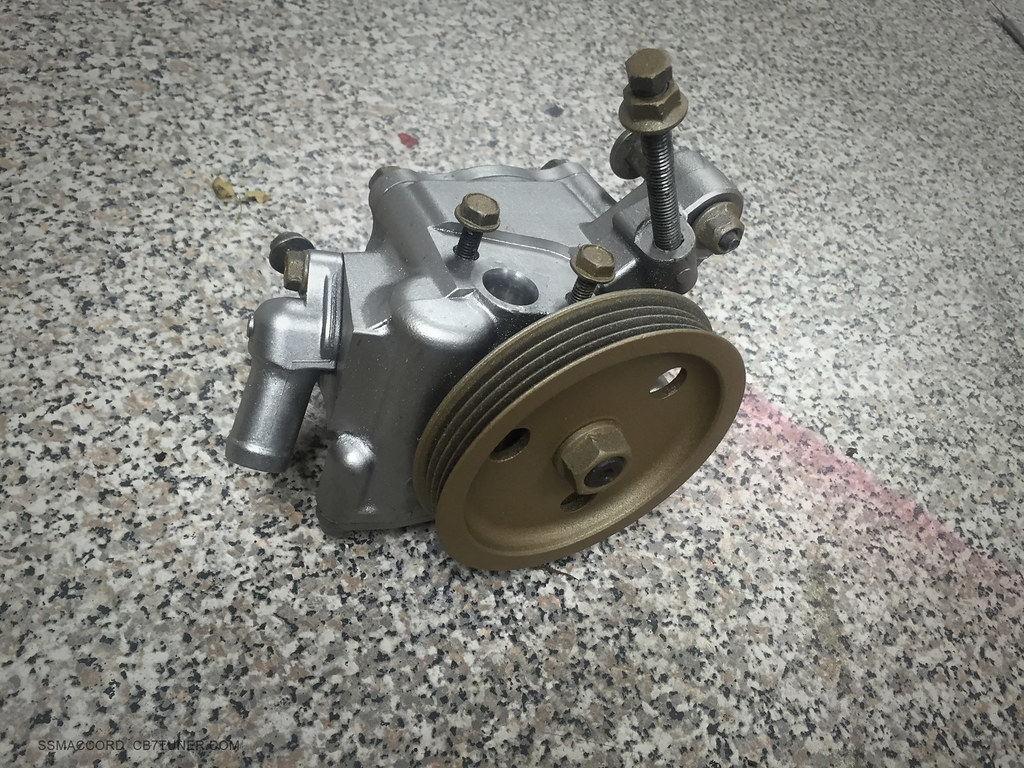

MR-S Electro-Hydraulic Power Steering Conversion

5 Lug Swap (98 Accord front/ prelude hub rear)

BC BR Coilovers

Moog Anchor Camber Mounts

SPC Balljoint Camber Kit (removed)

Hardrace Radius Rod bushings

Refreshed LCA's Front and Rear (I bought them ages ago and had them laying round when I was swapping the parts over from the old car)

New aftermarket Tie Rods

Prothane Urethane Bushing Master Kit

Progress Rear Stabilizer Bar

Lower Rear Strut Mount replaced w/ Urethane Bushing

ESP 3 Point Upper Front Brace

Ultra Racing 2 Point Upper Rear Brace

Spoon Rigid Collars (Front / Rear)

Battery Relocated to Trunk

BRAKES

ABS Delete

Goodridge G-Stop Stainless Braided Lines

Spoon Monoblock Calipers

13’ Drilled / Slotted Front Brake rotors

13” Fastbrakes rear rotors (cross-drilled and slotted)

Spoon Monoblock Calipers

CM Accord Hybrid Rear Caliper Brackets

TSW Nurburgring 17x7.5 +45 Offset

Dunlop Direzza Starspec III 215/45/17

FK8 Brake Cooling Ducts

Brake Shield Cooling Ducts

Powerstop Trackday Pads

Hawk HPS brake pads front/rear (track day) these are horrifically loud*

CL9 TSX OEM Wheels (storage)

DC5/AP1 OEM Calipers (removed)

DC2 10.2 Rear Brake Rotors (cross-drilled and slotted)

Stock springs, dampers, stabilizer bars

17x7 ??? Wheels, Black paint

Detroit Axle Remanufactured Steering Rack

INTERIOR:

Door panel vinyl wrap

Suede upholstered SE door inserts

Suede upholstered door lower to replace carpet

Leather wrapped door armrests

Sanded / painted map pocket trim / console trim

Transparent Red painted courtesy lights

eBay black door handles (painted black for gloss)

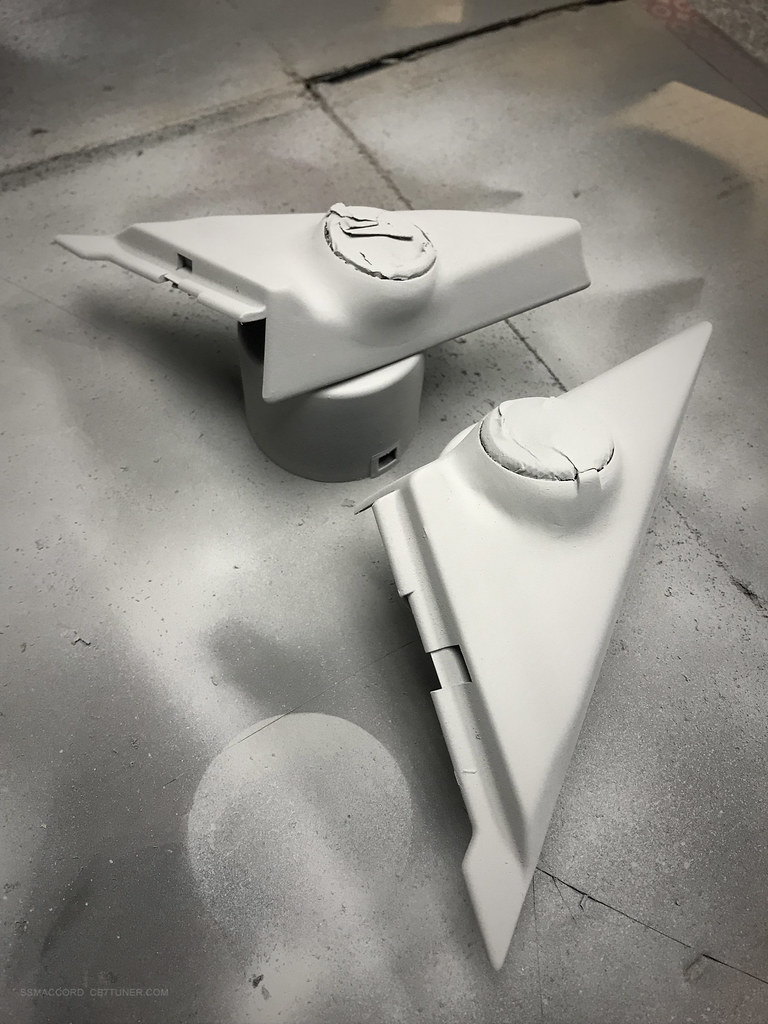

Suede wrapped A/B/C pillars/headliner/Sunvisor

SE Black Leather Rear Seat

RL Grab Handles (leather wrap)

CD5 Column Swap

CL1 Euro-R Steering Wheel

P-Spec Short Shifter

FFC Shifter Bushing /Shifter Plate Bushings

TLX Frameless Mirror

LED High Mount Brake Light

BB6 Cluster Swap

CL1 Euro-R Recaro seats

Black IP Swap

KA Legend Automatic Climate Control

Chrome HVAC Toggles

Honda Type-R Titanium Shift Knob

Leather E-Brake Handle / Body

White LED conversions

CRV Window switches with LED mod

Mirror Mount Tweeters

CD Intermittent Wiper Conversion

KA Legend Stalk Boots

M139 Stainless Steel Carpet Protector

Honda Stainless Sillplates

Sony Headunit

VW One Touch Blinker Retrofit

Stock Interior, R014L Vintage Red

Random amounts of coins

Cup filled with Cigar Tobacco

USB Cables

A-Pillar Mounted Tweeters

EXTERIOR:

46G Machine Gray

JDM/EDM Side Moldings

EDM License Plate Trim

S14 Aftermarket Front Lip

JDM One Piece Headlamp w/ E46 Bi-Xenon Retrofit (needs updating)

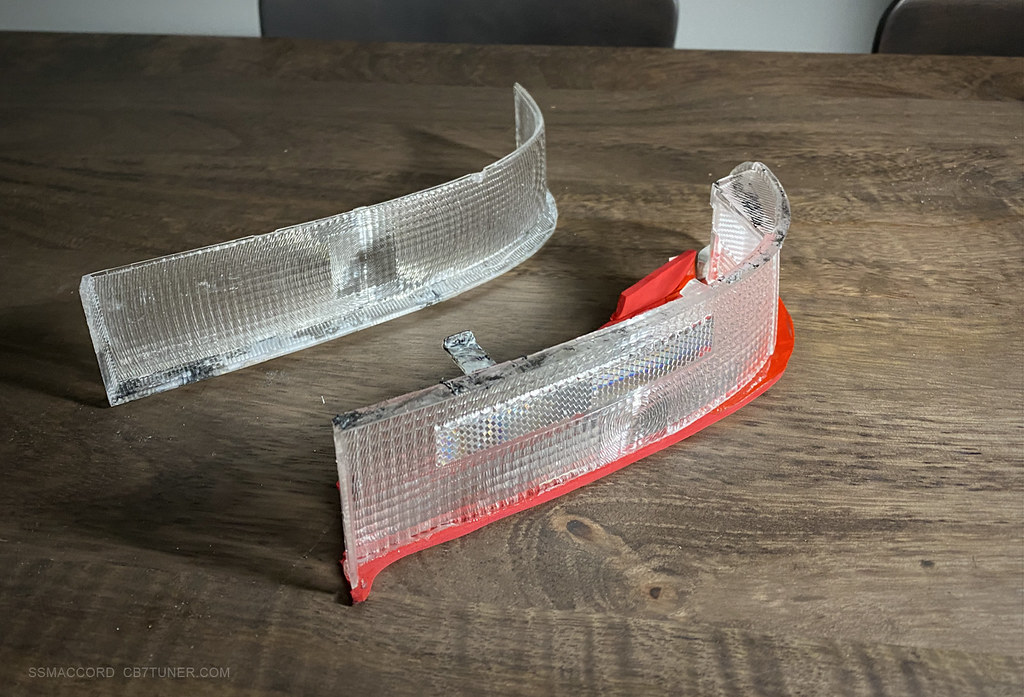

Euro Clear Bumper Lights (DIY SI-T Modded)

JDM SI-T Orange Clear Bumper Lights

Modified LED Red/Clear Taillamps

Ford Focus LED License Plate Lamp

Seattle Silver YR-94M

Clear Corner

Rusty Quarter Panels

Failing Clearcoat

Dents, dings

Misc. Stickers

Also, the pump I bought showed up without the plugs that were listed in the ebay ad so I had to source new parts and assemble them for my purposes. The high pressure hose is a unit from Karcepts. Since Toyota no longer supplies fluid for the system and standard Honda PS fluid is too viscous for the pump, I am running Nissan EHPS fluid.

Also, the pump I bought showed up without the plugs that were listed in the ebay ad so I had to source new parts and assemble them for my purposes. The high pressure hose is a unit from Karcepts. Since Toyota no longer supplies fluid for the system and standard Honda PS fluid is too viscous for the pump, I am running Nissan EHPS fluid.

\

\ .

.

I scrolled to post the same thing. Looks like he threw in a cheap lunch!

I scrolled to post the same thing. Looks like he threw in a cheap lunch!

Comment