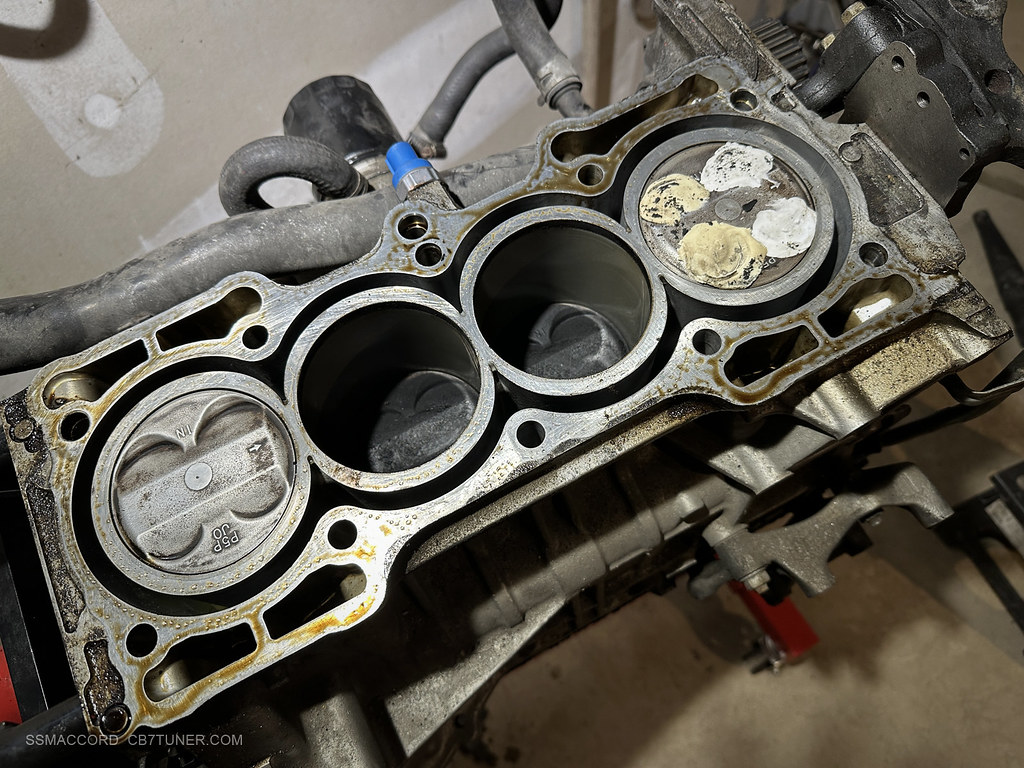

Upon trying to start the car the coolant got pumped into the engine and I hydro-locked it. It was a sad day, and a big lesson learned! I had to send the block off to a shop to have them fix my mess because I was young and had no clue what I was doing. I felt horrible as I killed the car. Now I label all hoses when removing the engine, unless it's obvious what goes where (like the alternator).

Upon trying to start the car the coolant got pumped into the engine and I hydro-locked it. It was a sad day, and a big lesson learned! I had to send the block off to a shop to have them fix my mess because I was young and had no clue what I was doing. I felt horrible as I killed the car. Now I label all hoses when removing the engine, unless it's obvious what goes where (like the alternator).I always wanted the BB6 just because you can get the flywheel cover that bolts to the pan and also the transmission. But that pan has no oil baffles in it; so I told myself if I'm going to buy another oil pan I should get a racing one with proper baffles in it. So I'm jealous if you get this done as I always with I had a baffled BB6 pan with the flywheel protector plate. There's a shop that will weld these baffles into the pan for you?

Leave a comment: