So not sure if you recall me asking if there was a way to tighten a loose vband clamp a couple months ago? Anyways, my wastegate dump tube is v band that I purchased from a person local. I believe the clamp is slightly too big so over time with the vibrations of the engine my dumptube which is normally angled down and towards the driver side wheel slowly starts to rotate pointing directly down to the ground. I have never had it actually touch the traction bar when it does this. Usually I can hear it rattle slightly between the wastegate outlet and the dump tube. So I would tighten the clamp and continue on my way. Not the tube and traction bar.

So when I went to inspect the dumptube when the noise first came about the pipe and clamp were tight and didn't look like they shifted at all. So I didn't think it was that and it also sounded different from what I'm use to hearing. A way to combat this from happening again in the future is having a bracket welded on the pipe and bolting it to the block or traction bar.

Announcement

Collapse

No announcement yet.

Grumpys93 : 1993 Accord LX

Collapse

X

-

You found metal in the oil if I remember correctly, so in my opinion this was not wasted effort. Just good preventative maintenance and peace of mind.

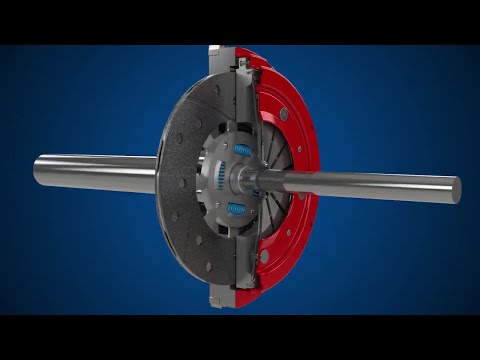

Raf when the clutch isn't depressed our throw out bearings are not engaged therefore not spinning. They rest on the transmission housing itself and not the input shaft, so there is no spinning in the center for them. The face engages the pressure plate and then spins. They only make noise when shot and engaged.

Leave a comment:

-

I'm guessing it's your clutch release bearing. Like a bad spot on one of the balls of the release bearing. When you put pressure on it, it tightens up and can't "bang around". With your foot off the clutch the shaft is rotating the bearing (maybe it's stuck as well) and you've worn a flat spot on it or the bearing. It could also be a broken tooth of the pressure plate. There's nothing else in there doing a rotational thing, and I'm guessing your issue sounds like a rotational "knock". Does the knock change with rpm?

Leave a comment:

-

OMG. On the one hand it was nothing serious, on the other hand that was a lot of unnecessary labor! I am glad that your quest was successful though.

Leave a comment:

-

I’m super embarrassed to say this but I have found my source of the knock and it was my wastegate dump tube hitting against my traction bar….. At least now I know I have fresh rod and thrust bearings….

Leave a comment:

-

Woah Buddy! Nah I’m building the h up now. Just dropped it off today to get sleeved. But the Accord will only see an F series in it. I have a feeling it’s something with the trans. But I have one more test to confirm it’s not the engine.

Leave a comment:

-

This is remind me of taking multiple-choice tests when I went to school for automotive, and the teacher would throw in an option for laughs:

D) Replace long block.

Time for a K-swap, buddy!

Leave a comment:

-

Sadly sounds like it's time to yank the trans then. Unless you can find anything via the inspection plate.

Leave a comment:

-

Ok so next update. Threw new thrust washers in and knock is still there. Again it goes away once I put the clutch it. It sounds like it near the trans side. But kind of hard to tell. Any other ideas?

Leave a comment:

-

The oil pump, pumps oil into the crankshaft itself. Honda machined passages all throughout the crank to carry oil from the snout to the end. It then feeds oil to the rod bearings via the holes in the crank. These fill the rod bearings as the crank is spinning. Each time the rod bearing hole aligns with the crank it gets an additional shot of oil up the rod itself that oils the wrist pin. Then the excess oil is just draining off of the crank and under the pistons. The squirters are there to lubricate the walls, but also cool the pistons. Unoiled pistons will run quite a bit hotter than oiled pistons. The oil is much much cooler than the combustion happening at the top of the piston. I think this is one of the main reasons an H22 engine handles boost better than the F series engines. Or they can run tighter clearances on the pistons and rings due to the extra cooling.

Think of how you can throw a Jackson Racing supercharger on a stock H22 engine and they will last over 50k+ miles or many many more. We throw a little turbo on a F22 engine stock and the ring land ends touch and the engine dies. More expansion due to heat in the pistons and rings.

Back on the real topic here. I truely do think it's the thrust washers. Any amount of wear will cause a noise. The slight pressure of the clutch being depressed is shifting the crank over and off of the thrust washer, eliminating the noise. A bad throw out bearing will make no noise while the clutch is disengaged due to it's resting away from the pressure plate not spinning. Once you depress the clutch the throw out bearing moves toward the pressure plate, eventually making contact and having to spin the bearing. I had one that was so bad it was like 10 people standing there screaming at you, but only when the clutch was depressed, once let out, you would never know the throwout bearing was shot.

Leave a comment:

-

Hmmm…the flywheel in theory is a rigid part that is rigidly mounted to the crank. That should mean it wouldn’t move, but perhaps the flywheel has some flex under load from the pressure plate.

I will try to take a look, but I’m not near my car for the time being. Someone will probably chime in before then though.

Leave a comment:

-

Raf, that is my understanding as well. Not sure why bisi didn’t incorporate them into his rods.

Update: So took a video of the crank and it didn’t budge at all. Did a compression test and it was 205 across the board with a cold motor WOT. I did notice that the flywheel moves a hair when I push the clutch in when I was peaking through the timing hole. Not sure if this is normal or not.

If anyone could check theirs and let me know that would be awesome.

I bought thrust washers and I’m going to go ahead and install them just for peace of mind. Just curious if anyone has any other thoughts before I rip the trans out.

Leave a comment:

Leave a comment: