Sooo we got the VMS valve cover kit &.......... ug.. I'm not impressed. For the cost + shipping + duty fees ug.

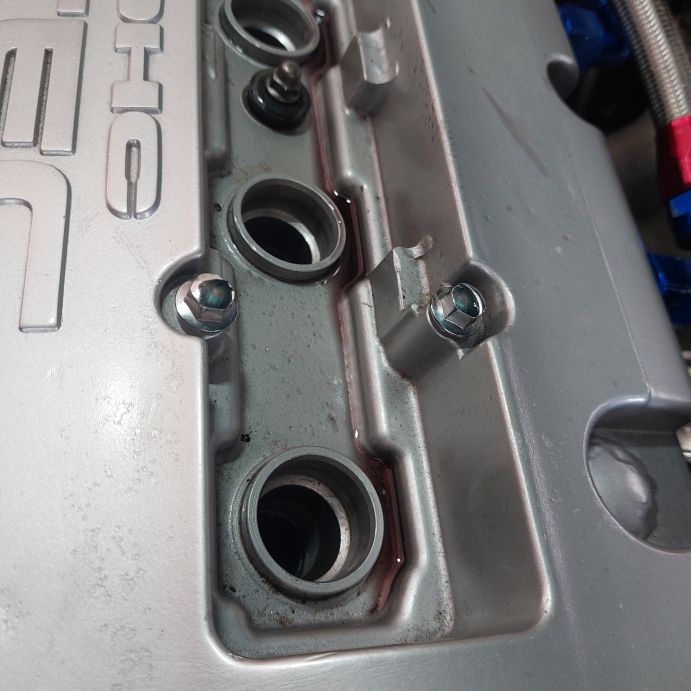

These "top hats" do have a fine rubber o-ring built into the bottom and top. Looks nice, but doesn't look robust.

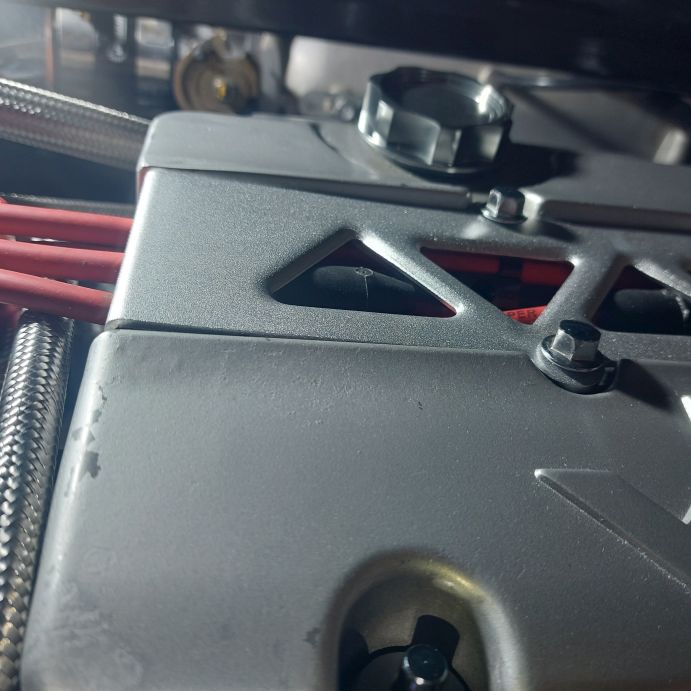

But the cover...... ug. ahhh ... wtf... I hate being tricked like this. #1... no way you're using this anywhere but a photo. and #2, even then it's garbage.

Even with the supplied washers it sucks...

Just no way I would allow the wires to rub in multiple spots like this. Even if you poke them out the top it's rubbing. the OEM has a dome shape for a reason.

Anywho...took the car for another 20km trip to the grocery store and the new valve cover nuts/seals did fix the problem

Back to dry valve cover.

Back to dry valve cover.

And problem #2 revealed itself. I went into turbo a bit and blew a intercooler piping clamp. Got home and realized I ordered the wrong size when replacing the previous one and this clamp was as tight as it could go, 73mm. I need 65mm or less (2.5" pipe). So ordered new clamps.

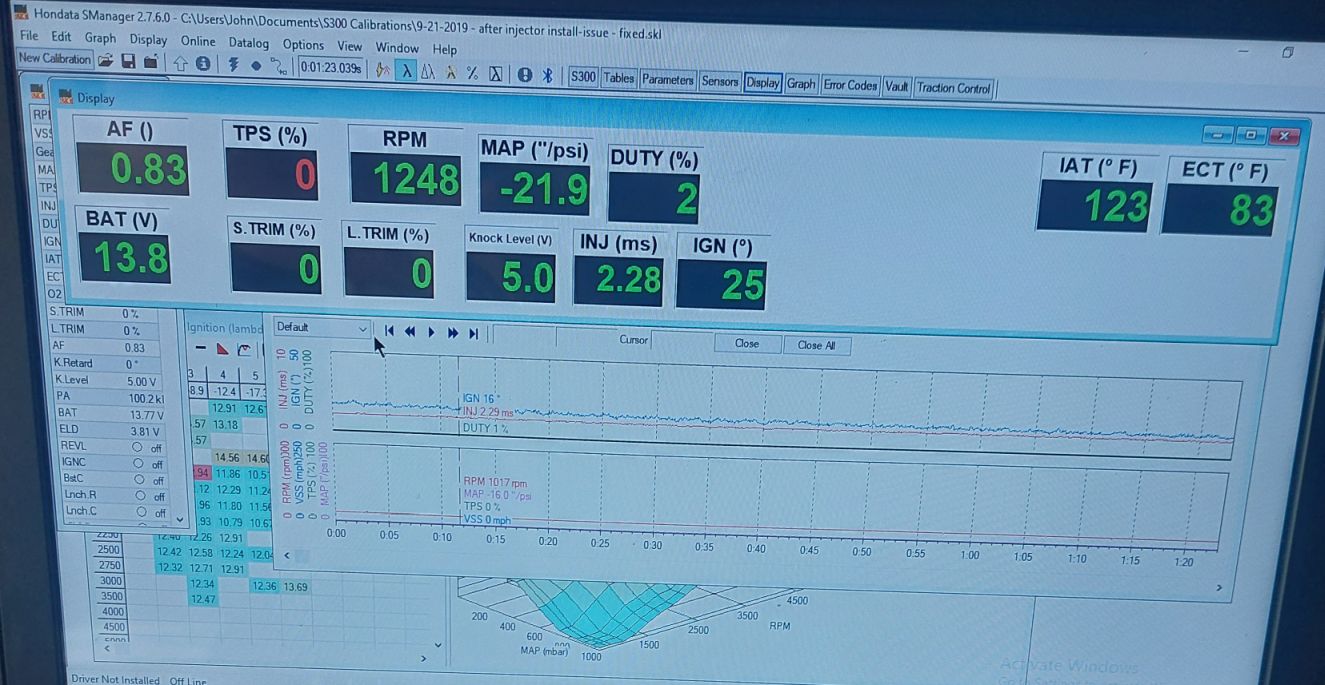

And it stalled when pulling in the driveway. I hate that I can't solve that issue. The ole... off the gas and on the brakes and idle drops too low. Even though S300 is set to 800 etc. it drops below it. Have long starts too... going to check all grounds and alt / power wires.

Besides that it runs great. I'm starting to believe I actually did this job successfully

. OK. ordering new hardware.

. OK. ordering new hardware.

Leave a comment: