Great info, thanks. Wish I had known about the RyWire hose before; avoiding that joint (and potential leak) between the two separate lines would have been nice. Something to remember for when I eventually get the engine bay painted, though. I'll see if I can figure out cruise and neutral safety just using the FSM, it shouldn't be too hard, but I'll let you know if I'm struggling, thanks.

Was there any change in performance with the S2000 master, or was it just appearance?

Announcement

Collapse

No announcement yet.

CyborgGT : 1993 Accord EX wagon

Collapse

X

-

Cyborg, all of the modifications to the transmission will be noticeable. When I rebuilt my M2Y4 and added a WaveTrac LSD, I also added the SpeedFactory detent springs and the mtec shifter springs. Only I have the shifter cables fully converted to derlin and the aluminum mounting plates from Shayspec which are no longer available. But the springs alone made a huge difference in shifter feel.

Also another option for the clutch line is a Rywire option from the master to the slave directly. Have a black plastic covering over the stainless braid.

Rywire B/D Clutch Line

http://www.rywire.com/product-p/clutch-line-b-d.htm

Rywire Accord/Prelude Clutch Line

http://www.rywire.com/rywire-accord-...-line-h12m.htm

I used the B/D one on Lola so I could keep it tucked against the firewall. I also have the S2000 master cylinder in place of the stock Accord one.

Also I can dig through my notes for anything you might need related to the auto to manual swap. I've done 2 successfully and am currently working on swapping a buddies wagon. This would include the cruise control and the neutral safety switch, requiring the clutch to be depressed to start the car.Last edited by Rilas; 12-11-2020, 05:03 PM.

Leave a comment:

-

For now I'm leaving them, but FFC makes billet aluminum replacements that I'll eventually try out.Originally posted by AccordWarrior View Post

Have you thought about removing the rubber isolators, or upgrading them to something firmer? You'd likely get some gear whine, but I would be curious if it would change how the shift felt.

Leave a comment:

-

*scribbles furiously in CB7 notebook to keep in mind for future modificationsOriginally posted by CyborgGT View Post

I got a basic Duralast clutch for the initial install and test, though (yay for holiday overtime at work), so unless I'm forgetting something I should be good to put the new transmission in this weekend. I found this stainless clutch line to replace the rubber one on top of the transmission as well, made by Phase 2 Motortrend. Unlike the Valex line to the master cylinder, this one has a clear rubber sleeve to protect against fraying. I'd never heard of the brand before, but it feels like a quality piece .

.

Leave a comment:

-

Have you thought about removing the rubber isolators, or upgrading them to something firmer? You'd likely get some gear whine, but I would be curious if it would change how the shift felt.Originally posted by CyborgGT View PostNext up was the Prelude shifter. Looking through the DIYs, it seems like everyone just forces the bolts into the bushings and tightens it down in that stressed position. I didn't like that, so I elongated the front holes so it all sits more relaxed before bolting down.

Shifter and pedals in!

I installed the ITR shift boot onto the console, and couldn't help mocking it up with the Circuit Hero extender and Skunk2 knob. That knob is so heavy for something so small, it's awkward to hold and I actually dropped it on the ground, so now it's got some little gouges in it. I'm feeling stupid for that...

Leave a comment:

-

What's different about the H22? I always thought the F & H blocks were basically identical as far as the exterior casting is concerned. But the fluid was only about 5 bucks a quart; I was expecting much more for OEM, so that was nice. I think once the H22 is running, I'll end up going back and forth between Honda and GM Syncromesh for a bit to see if I feel a real difference, but it sounds like people are having less problems with Honda's ever since they changed their formula.Originally posted by Raf99 View PostIt is a pain, especially with a H22! Looks good though, cost a lot for all that fluid and parts but sooo worth it as it's a wagon!! Sweet!

I got a basic Duralast clutch for the initial install and test, though (yay for holiday overtime at work), so unless I'm forgetting something I should be good to put the new transmission in this weekend. I found this stainless clutch line to replace the rubber one on top of the transmission as well, made by Phase 2 Motortrend. Unlike the Valex line to the master cylinder, this one has a clear rubber sleeve to protect against fraying (*ED. - correction: the Valex line does have a protective sleeve, it's just not as thick). I'd never heard of the brand before, but it feels like a quality piece .

.

Last edited by CyborgGT; 12-27-2020, 03:44 PM.

Last edited by CyborgGT; 12-27-2020, 03:44 PM.

Leave a comment:

-

It is a pain, especially with a H22! Looks good though, cost a lot for all that fluid and parts but sooo worth it as it's a wagon!! Sweet!

Leave a comment:

-

And the slushbox is out. What a pain in the back... upper and lower.

Can. Not. Wait. Until my sparkly-clean engine and trans are in. The wagon's definitely getting a trip to the car wash once the F22's out. The entire engine bay is this disgusting.

Came home afterwards to the rest of the parts I need from Honda, delivered a day early! Enough fluid for three quick changes, to really flush out whatever was in there before; pads for the clutch and brake pedals; clutch release fork boot; a couple drain plug washers; the output seals for the axles; and the reverse sensor that was missing.

Leave a comment:

-

I hope so too! I've never owned a manual car (the sedan and RSX being the only other cars I've owned), so I'm not as familiar with them and am doubly nervous, haha. I need to keep an eye on my budget, but I could have this running within the next two weekends. I just remembered I still want to get a stock-spec clutch for testing purposes, so I'm not wearing out the Exedy before the H22 goes in. I have a friend who's owned several manual cars, so he'll be making sure it feels as it should.

Leave a comment:

-

This is exciting. I have never done this, but I hope that it goes smoothly.

Leave a comment:

-

ARP flywheel bolts work, thankfully. Found some pressure plate bolts on eBay as well, which just arrived today. As I refresh this transmission and figure out what I still need, a cart at Majestic is building up...

Cleaned up the transmission as best I could. I have a bolt plugging the hole for the missing reverse sensor, but I'd rather get that new than from the junkyard, so that's in the Majestic cart. I did find a proper breather tube cap at the 'yard, though!

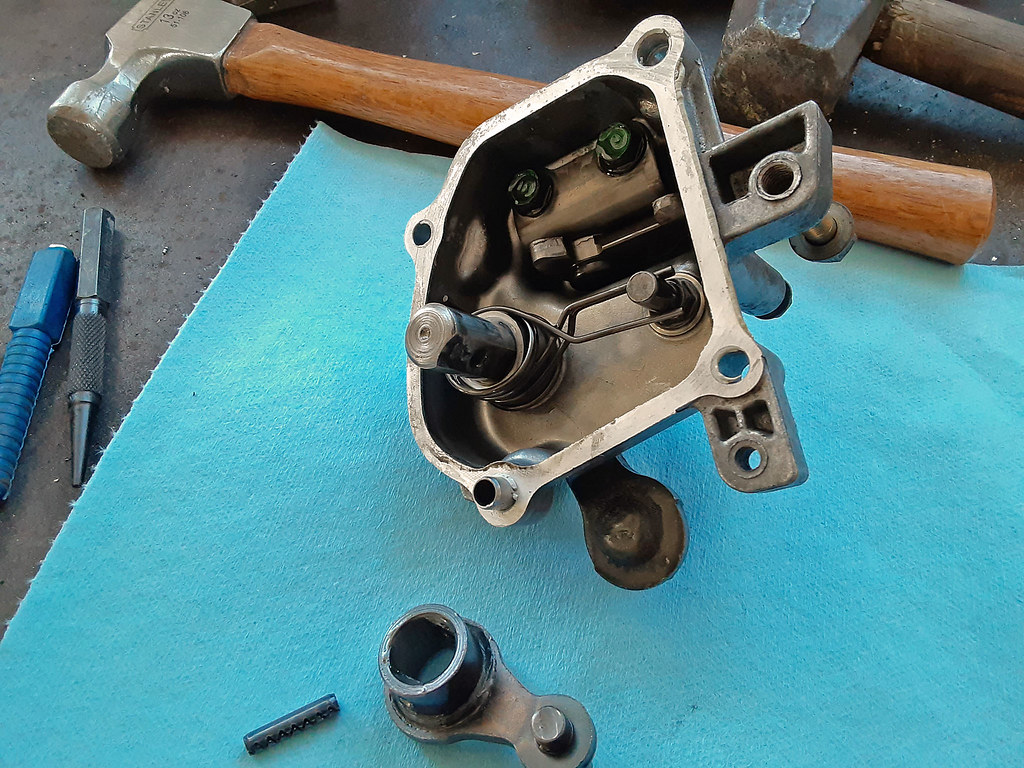

Installed the Speedfactory detent springs:

As well as the MTEC shift springs:

And the new slave:

Last edited by CyborgGT; 11-30-2020, 10:43 PM.

Last edited by CyborgGT; 11-30-2020, 10:43 PM.

Leave a comment:

Leave a comment: