Announcement

Collapse

No announcement yet.

CyborgGT : 1993 Accord EX wagon

Collapse

X

-

wow..... wish i could help. (and glad I don't have to go through this). All these measurements are coming out the tailpipe?

Leave a comment:

-

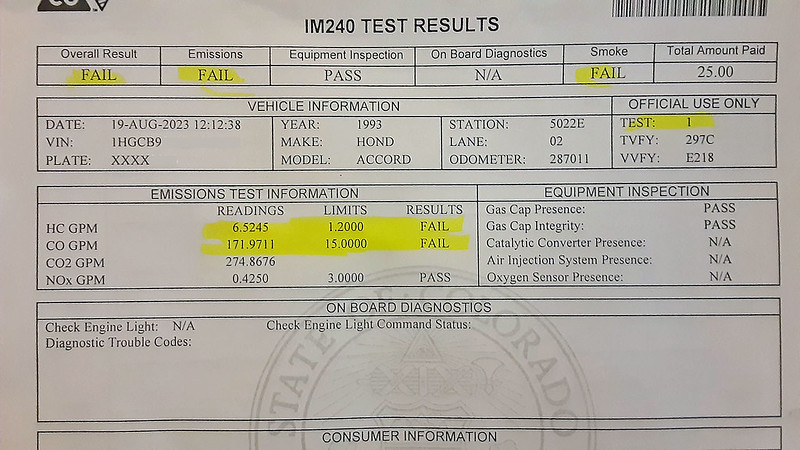

And yet another potentially long delay before this car's in the clear, after failing emissions pretty spectacularly.

This was right after the tune:

The tech there suggested the CO number was a "massive vacuum leak." I took the car home and looked it over, found that the brake booster hose was dried out on the inside, so I replaced that. I also tightened down the nuts on the thermal intake manifold gasket a bit more. Went back in and while there was a significant improvement, it's still way the hell off the charts.

The car was noticeably better to drive though, so the vacuum leak explains why the tuner had trouble getting it to idle. I feel kinda confident that it's not my lack of EGR, or NOx wouldn't be so far under the allowed limits. Researching that a bit, it sounds like EGR attacks NOx at the expense of increased CO and HC emissions anyway (why it's even such a hot-button issue with the EPA these days is confusing the hell out of me). I feel like with how close the HCs are, it's probably the tune running rich just to get it to idle; the tuner feels the same - and he did say he wouldn't charge me for a re-tune while I figure this out. I did delete the EVAP canister, and at this point I can't remember if my reasoning was related to the 'black box' that I deleted because I now have a throttle body-mounted MAP sensor and no EGR. Is the charcoal canister even plugged into that box? From what I'm reading, a malfunctioning (i.e. missing) EVAP could contribute to "excessive" CO emissions and a rich running condition.

I'm really, really hoping it's not my cams, knowing that cams can have a big impact on engine vacuum. I'll try to hook the EVAP canister back up and get the tune double-checked, but can the EVAP have that much of an impact on CO?.

Thoughts?

Oh, and my cam seals might have just needed to 'break in,' because after the dyno session and these two hour-long drives for emissions, it hasn't leaked a drop. Still have two new OEM seals on stand-by...Last edited by CyborgGT; 08-23-2023, 03:20 PM.

Leave a comment:

-

Damn that was great sounding.

Super healthy tune at that too, I saw zero smoke of any kind whatsoever.

My tunes were always too rich as WOT would cause black smoke.

But this is all before a wideband.

Leave a comment:

-

Sounds great! It's a fun acceleration too, especially for the wagon! Long ago I only had the F22...and I remember going for a drive in my friend's prelude. All I could think was " ahh..it keeps pulling into the high rpms. " was always so fun.

Leave a comment:

-

This is a milestone at least. It seems like other than the atmospheric effect the car was running soundly. I can’t wait to see the video from the dyno. Hopefully after your emissions appointment you’ll be able to take it for a bit of a drive.

Leave a comment:

-

Well.... it's a good base. We can say that for sure. A small turbo to take it to 300HP would work while keeping the 2 5" exhaust.

Leave a comment:

-

Yes, they're functional... at least in theory, haha. There's a hose coming off my enclosed intake filter that routes to that now empty space behind the bumper. I'm hoping that with this design, I'm getting the benefits of a real "cold air intake" without the risk of hydrolock.Originally posted by Grumpys93 View PostDude that look awesome! I like the little ducts, I can't remember, but those are fuctional correct?

Yesterday was dyno day... and it was quite anticlimactic. I learned a lot.

- Living at elevation (me at 5,000+ ft) SUUUUUUUCKSS. Researching almost identical builds to mine online, even in our own all-motor records list, I was expecting to make more power. I ended up making 202 at the wheels. Sadly, this went down at PFI, who for some reason don't seem interested in hooking up their dyno to read torque. I was told I might gain 20hp with E85, but I'm not interested - I imagine it won't be available in a mainstream way for much longer anyway. I think VTEC was set at around 6500 to smooth out the transition, even though it's still a loud crossover. Fuel cut looked to be right at 8k, if my tach is accurate. Power starts to drop off a bit after 7k.

- That said, a small turbo is definitely in this car's distant future, if it's possible to clear factory accessories. I'm definitely not ditching p/s or a/c for that. Before then, though, I do want to experiment with more all-motor mods to see if I gain anything significant. At least a better header (HyTech, if possible) and K-series intake manifold (S2 Ultra Street). I'll probably upgrade to FuelTech eventually as well. Part of me is taking this whole experience as a challenge, haha.

- Maybe it's because I've only ran the car in shop-like atmospheres and the storage center, where poor acoustics is a thing, but the exhaust is overly loud and really boomy down low. My 3" back section will be reduced to 2.5" to match the rest of the system ahead of the gas tank in an effort to try to quiet it a bit. I'll do that when I get the coilovers that I need to tuck the back of the exhaust up higher anyway.

- Evidently I've got electromagnetic interference going on, because the tuner was having trouble connecting his laptop to the ECU. He says it shouldn't affect drivability, though. I'm thinking it might be because of all the gauges I have in the glovebox and the proximity of their wiring to the ECU's USB cable, but I'll have to figure that out.

I did get a video of one of the final pulls, I'll post that soon. And I should be getting the car to an emissions center in the next few days; Colorado's inspections are still pretty lax, but that'll be an interesting experience.Last edited by CyborgGT; 08-15-2023, 10:57 AM.

Leave a comment:

-

Dude that look awesome! I like the little ducts, I can't remember, but those are fuctional correct?

Leave a comment:

-

The cat was indeed installed Thursday, and then he spent some time that evening working on the tune at idle. Over text, he was pretty complimentary about the car and the engine, saying it sounded really good. He upped the duty cycle on the IACV and says it's idling really nice now. Just a bit lopey because of the cams, but who doesn't enjoy some cam lope? At this point, he's just waiting on some open dyno time at one of a few shops in the area.

In the meantime, here's an updated exterior shot from when we were loading the car onto a trailer...

It's come a long way.

Last edited by CyborgGT; 08-14-2023, 10:28 AM.

Last edited by CyborgGT; 08-14-2023, 10:28 AM.

Leave a comment:

Leave a comment: